Your Ultimate Custom Rose Gold Filled Earrings Jewelry Factory in China

Makes custom jewelry supplier

LET’S GET STARTED : mo@kingjy.com

JINGYING: Your Ultimate Custom Rose Gold Filled Earrings Jewelry Factory in China

In the ever-evolving world of fashion and personal adornment, few accessories hold the transformative power of a perfect pair of earrings. They frame the face, express individuality, and can serve as a signature piece that defines a personal style. Among the myriad of choices available to consumers and brands today, rose gold filled earrings have emerged as a dominant force, beloved for their warm, flushing hue that complements all skin tones, their contemporary elegance, and their accessible luxury. This meteoric rise in demand, however, places immense pressure on brands, designers, and retailers to source not just any product, but the right product: impeccably crafted, ethically produced, and perfectly aligned with their vision and values.

The global jewelry supply chain is vast and complex, but for those seeking quality, customization, and scalability, one destination consistently rises to the top: China. And within China’s sophisticated manufacturing landscape, one name has become synonymous with excellence in the niche of custom rose gold filled earrings—JINGYING. More than just a factory, JINGYING represents a partnership, a promise of quality, and the ultimate source for turning creative concepts into tangible, market-ready treasures. This article delves deep into the world of JINGYING, exploring why it stands as the unparalleled choice for businesses looking to master the art and science of rose gold filled earring production.

Decoding the Allure: Why Rose Gold Filled?

Before understanding the manufacturer, one must first appreciate the material itself. The term “rose gold filled” is specific and signifies a tier of quality far superior to mere plating.

- The Composition of Rose Gold: Traditional rose gold is an alloy of pure gold, copper, and a touch of silver. The distinctive pinkish-red color comes primarily from the high copper content. The karat (e.g., 14K) denotes the percentage of pure gold in the alloy (14K is 58.5% gold).

- The “Filled” Advantage: Gold filled material is not a plating or a wash. It is a sophisticated metallurgical process where a thick layer of solid rose gold (typically 5% or 1/20th of the total weight by law in the US) is permanently bonded to a core of high-quality jewelers’ brass under immense heat and pressure. This process creates a durable, long-lasting product.

- Contrast with Other Methods:

- Vs. Gold Plated: Plating involves depositing a microscopic layer of gold (often less than 0.5 microns) onto a base metal via electrolysis. This layer is extremely thin, prone to tarnishing, and will wear off quickly with regular use, exposing the base metal underneath.

- Vs. Vermeil: Vermeil is a specific type of heavy gold plating (must be at least 2.5 microns thick) over sterling silver. While higher quality than standard plating, it is still a surface-level coating and can eventually wear, though the sterling silver base is more noble.

- Vs. Solid Gold: Solid gold is the pinnacle of purity but comes with a prohibitively high cost for many brands and consumers. It is also a softer material, making it less ideal for certain intricate designs that require rigidity.

Rose gold filled strikes the perfect balance. It offers the substantial look, feel, and durability of solid gold at a fraction of the price. The thick gold layer makes it highly tarnish-resistant, hypoallergenic, and durable enough to last for decades with proper care. It is the material of choice for brands that want to offer their customers heirloom-quality jewelry without the heirloom price tag. For a factory like JINGYING, mastering this material is paramount, requiring precise control over alloy composition, bonding techniques, and finishing processes.

The Chinese Manufacturing Ecosystem: A Powerhouse of Precision

The decision to manufacture in China is a strategic one, driven by a confluence of factors that create an environment unmatched anywhere else in the world.

- Centuries of Artisanal Heritage: China has a deep and rich history in goldsmithing and fine jewelry craftsmanship. This traditional skill base has seamlessly integrated with modern technology, creating a workforce that is both artistically skilled and technically proficient.

- Unmatched Industrial Clustering: Cities like Shenzhen and Guangzhou have become global epicenters for jewelry manufacturing. This clustering creates an incredibly efficient ecosystem. Within a small geographic radius, one can find specialized suppliers for everything from precision casting machines and laser welders to diamond cutters and gemstone dealers. This drastically reduces lead times and logistical complexity.

- Technological Prowess: Chinese factories are at the forefront of adopting advanced manufacturing technologies. Computer-Aided Design (CAD), 3D printing for rapid prototyping, automated polishing systems, and precision laser cutting are standard tools, ensuring unparalleled accuracy and consistency.

- Scale and Flexibility: A common misconception is that Chinese manufacturing is only for massive, high-volume orders. While they excel at scale, leading factories like JINGYING have perfected the art of “agile manufacturing.” They can efficiently handle small-batch production runs for emerging designers while also possessing the infrastructure to ramp up to millions of units for global retail giants. This flexibility is crucial in today’s fast-paced market.

- Cost-Effectiveness: The combination of efficient supply chains, skilled labor at scale, and advanced technology results in a superior cost-to-quality ratio. This allows brands to achieve healthy margins while delivering exceptional value to their end customers.

Within this powerful ecosystem, JINGYING has carved out its dominance by focusing relentlessly on one specific segment: custom rose gold filled earrings.

JINGYING: The Anatomy of an Ultimate Factory

The name “JINGYING” (精英) in Chinese translates to “elite” or “cream of the crop,” a title the company strives to embody in every aspect of its operation. Here’s what makes it the ultimate partner.

1. Philosophical Foundation: A Partnership, Not Just a Transaction

JINGYING’s core philosophy is built on collaboration. They understand that they are not merely executing a purchase order; they are helping to build a brand. Their team approaches each project with a mindset of partnership, offering insights from design feasibility to market trends. They become an extension of their clients’ teams, providing expert guidance to ensure the final product is not only manufacturable but also commercially viable and beautiful.

2. The End-to-End Process: From Concept to Collection

JINGYING’s integrated process is designed for seamless, worry-free production.

- Stage 1: Vision and Consultation. It all begins with a conversation. Whether a client has detailed CAD drawings, hand-sketched ideas, or just a mood board, JINGYING’s project managers and engineers engage in a deep-dive consultation. They discuss target audience, price points, aesthetic goals, and functional requirements.

- Stage 2: Design Engineering and CAD. This is where art meets science. JINGYING’s in-house CAD designers are artists in their own right. They translate concepts into precise 3D digital models, optimizing the design for manufacturing. They advise on structural integrity, weight distribution for comfort, and the most efficient use of materials to control costs without compromising on design intent.

- Stage 3: Rapid Prototyping. Once the CAD model is approved, it is sent to one of JINGYING’s high-resolution 3D printers. A physical prototype, or “sample,” is produced in a hard wax or resin material. This allows the client to hold the design, check the proportions, fit, and overall feel. This iterative process is crucial, and JINGYING facilitates it quickly, often turning around samples in a matter of days.

- Stage 4: Mold Making. After the prototype is finalized, a master model is created and used to produce a precise steel mold for the casting process. The quality of this mold is critical for capturing every minute detail of the design in subsequent production runs.

- Stage 5: Casting and Formation. The core brass of the rose gold filled material is cast using the mold. JINGYING employs advanced vacuum casting machines that ensure a bubble-free, perfect reproduction of the design every time. For sheet-based designs, they use precision stamping and laser cutting.

- Stage 6: The Gold Bonding Process. This is JINGYING’s crown jewel. The brass components undergo a meticulous process to permanently bond the layer of solid rose gold. This involves strict controls over temperature, pressure, and timing to ensure a perfect, durable, and consistent bond that meets or exceeds international standards (e.g., US standards requiring 1/20th of the total weight to be gold).

- Stage 7: Assembly and Setting. For earrings with gemstones, pearls, or intricate components, skilled artisans take over. Using microscopes and micro-laser welders, they set stones with impeccable precision and assemble parts with a focus on strength and aesthetics. Every clasp, jump ring, and post is scrutinized.

- Stage 8: Finishing and Polishing. This step defines the final character of the piece. JINGYING offers a vast array of finishes:

- High Polish: A brilliant, mirror-like shine.

- Matte/Satin: A soft, brushed, non-reflective finish.

- Sandblast: A textured, rough finish.

- Antique/Rose Gold Plating: A two-tone effect where recessed areas are plated a different color for contrast.

Polishing is done by hand and machine to achieve a flawless surface that is smooth to the touch.

- Stage 9: Rigorous Quality Control (QC). This is non-negotiable. Every single earring undergoes a multi-point inspection. QC checks include:

- Dimensional Accuracy: Verifying size and proportions against the CAD model.

- Surface Quality: Inspecting for scratches, pits, or polishing marks.

- Stone Check: Ensuring stones are secure, undamaged, and properly aligned.

- Functionality: Testing posts, clutches, hooks, and clasps for security and ease of use.

- Gold Layer Integrity: Using advanced tools to verify the thickness and consistency of the gold layer.

- Stage 10: Packaging and Logistics. JINGYING understands that unboxing is part of the brand experience. They offer custom packaging solutions—from branded boxes and pouches to care cards and certificates of authenticity. Finally, they manage the entire logistics chain, ensuring timely and secure delivery to any destination in the world.

3. Unwavering Commitment to Quality and Ethics

JINGYING’s reputation is built on trust. This is fostered through:

- Material Traceability: They source metals and gemstones from reputable, certified suppliers, providing assurances against conflict materials.

- Certifications: Compliance with international standards like ISO 9001 for quality management systems is standard practice.

- Ethical Labor Practices: JINGYING maintains a safe, modern, and professional working environment, believing that a valued workforce produces the best work.

- Transparency: Clients are encouraged to visit the factory for audits and to see the production process firsthand. Virtual tours and regular production updates are also standard.

4. A Portfolio of Possibilities

JINGYING’s expertise spans the entire spectrum of earring styles:

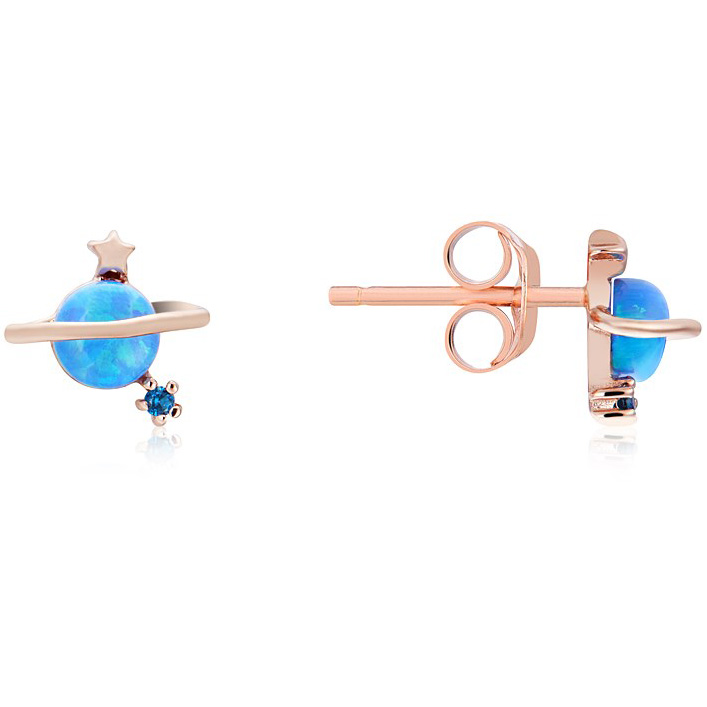

- Stud Earrings: From simple solitaire gemstones to intricate geometric shapes and custom initials.

- Hoop Earrings: Seamless, lightweight, and perfectly circular hoops in various diameters and thicknesses.

- Drop and Dangle Earrings: Elegant, movement-driven designs that capture light.

- Huggies: The perfect hybrid between a stud and a hoop, hugging the earlobe.

- Threader Earrings: Modern, minimalist designs that thread through the ear.

- Statement Earrings: Bold, architectural pieces that are the centerpiece of any outfit.

The Competitive Edge: Why Brands Choose JINGYING

Choosing JINGYING translates into tangible benefits for a brand:

- Speed to Market: Their efficient process and rapid prototyping get products from idea to inventory faster.

- Superior Product Quality: The rigorous focus on craftsmanship and QC results in products that reduce returns and build brand loyalty.

- Innovation and Expertise: Access to their designers and engineers helps brands create unique, technically sound designs that stand out.

- Scalability: They grow with you, from your first small order to mass production.

- Profitability: The excellent cost structure allows for strong retail markups while remaining competitive.

Conclusion: Forging the Future, One Pair at a Time

In the competitive landscape of jewelry, the right manufacturing partner is the most critical asset a brand can have. JINGYING is not just a factory; it is a center of excellence, a hub of innovation, and a guarantor of quality. For any brand, designer, or retailer looking to make their mark in the world of fine jewelry with custom rose gold filled earrings, the path to success leads directly to their doors. By combining ancient craftsmanship with cutting-edge technology, a partnership ethos, and an unwavering dedication to the unique beauty of rose gold filled material, JINGYING truly earns its title as the ultimate custom rose gold filled earrings jewelry factory in China. They don’t just manufacture earrings; they help forge legacies.