925 Sterling Silver Necklace Jewelry Manufacturer & Supplier – Your OEM Factory in China

Makes custom jewelry supplier

LET’S GET STARTED : mo@kingjy.com

JINGYING: 925 Sterling Silver Necklace Jewelry Manufacturer & Supplier – Your OEM Factory in China

In the vast and intricate tapestry of the global jewelry industry, few materials possess the timeless allure, universal appeal, and versatile potential of 925 sterling silver. As a cornerstone of fashion, personal expression, and accessible luxury, sterling silver necklaces serve as a blank canvas for brands, designers, and retailers worldwide. They can be minimalist statements of elegance, bold carriers of meaning, or intricate works of art. However, the journey from a spark of inspiration to a finished product adorning a customer’s neck is fraught with challenges: ensuring material purity, mastering complex craftsmanship, achieving cost-effectiveness, and scaling production to meet demand.

For those looking to navigate this complex journey successfully, the global epicenter of jewelry manufacturing offers a clear solution: China. Within this powerhouse of production, a name emerges not just as a manufacturer, but as a strategic partner dedicated to excellence in sterling silver—JINGYING. This article delves deep into the world of JINGYING, positioning it as the ultimate OEM factory and supplier for 925 sterling silver necklaces, exploring its processes, philosophies, and the unparalleled advantages it offers to businesses aiming to conquer the market.

The Enduring Legacy of 925 Sterling Silver

To understand JINGYING’s mastery, one must first appreciate the material at the heart of its operation. Sterling silver is more than just a metal; it is a standard of quality and a testament to enduring value.

- The “925″ Standard: Pure silver, known as fine silver (99.9% pure), is too soft for most jewelry applications. It is prone to scratching, bending, and losing its shape. To create a durable yet beautiful material, fine silver is alloyed with 7.5% other metals, almost always copper. This results in a metal that is 92.5% pure silver—hence the “925″ stamp, a universal hallmark of authenticity and quality. The copper adds strength and rigidity without significantly compromising the brilliant white luster of the silver.

- Why Sterling Silver? The popularity of sterling silver is no accident. It is:

- Hypoallergenic: Its high purity makes it suitable for most people with metal sensitivities, unlike many base metals or low-quality alloys.

- Durable: With proper care, sterling silver jewelry can last for generations, often becoming heirlooms.

- Versatile: Its neutral, bright white color provides the perfect backdrop for a vast array of designs. It can be polished to a mirror shine, given a matte satin finish, or oxidized to create antique, vintage effects. It complements every gemstone, from the fiery sparkle of diamonds to the deep hues of sapphires and the organic beauty of pearls.

- Accessible: It offers the look and feel of luxury precious metals like platinum or white gold at a fraction of the cost, making fine jewelry accessible to a much wider audience.

For a manufacturer, working with sterling silver requires specific expertise to prevent tarnishing (a natural reaction with sulfur in the air), ensure precise casting, and execute flawless finishing. This is where JINGYING’s specialized knowledge becomes invaluable.

The Chinese Manufacturing Juggernaut: A Ecosystem of Excellence

The decision to source jewelry manufacturing from China is a strategic one, driven by a confluence of factors that create a manufacturing environment unparalleled in its efficiency and capability.

- Historical Artisanship Meets Modern Technology: China has a millennia-old tradition of metalworking and jewelry crafting. This deep well of artisanal skill has been seamlessly integrated with state-of-the-art technology. The result is a workforce that possesses both the intuitive touch of a craftsman and the technical precision of an engineer.

- The Shenzhen and Guangzhou Clusters: These cities are globally recognized as hubs for jewelry production. This clustering creates an incredibly efficient and synergistic ecosystem. Within a small radius, a factory like JINGYING has immediate access to every conceivable specialist: mold-makers, casting machine manufacturers, gemstone wholesalers, chain specialists, tooling experts, and packaging suppliers. This drastically reduces lead times, minimizes logistical costs, and fosters a culture of continuous innovation and knowledge sharing.

- Technological Supremacy: Leading Chinese factories are not manual workshops; they are advanced manufacturing centers. They leverage technologies like:

- Computer-Aided Design (CAD): For creating intricate, precise, and modifiable 3D models.

- 3D Printing (Rapid Prototyping): For producing accurate wax or resin models within hours, allowing for rapid iteration and design validation.

- Automated Casting and Finishing: Computer-controlled machines ensure consistency and quality in large production runs.

- Laser Welding and Cutting: For unparalleled precision in assembly and detail work that is impossible to achieve by hand.

- Unmatched Scalability and Flexibility: A common misconception is that Chinese manufacturing is only for massive orders. While they excel at high-volume production, top-tier factories like JINGYING have mastered agile manufacturing. They can efficiently and profitably handle small Minimum Order Quantities (MOQs) for startup brands and custom designers, while simultaneously possessing the infrastructure to fulfill orders for tens of thousands of units for international retail chains. This flexibility is critical in the fast-paced, trend-driven fashion world.

- Superior Cost-Effectiveness: The combination of efficient supply chains, technological automation, and skilled labor at scale results in the best possible cost-to-quality ratio. This allows brands to maintain healthy profit margins while offering exceptional value to their customers, a key competitive advantage in any market.

Within this powerful context, JINGYING has distinguished itself by focusing its expertise on a specific domain: the end-to-end OEM production of premium 925 sterling silver necklace jewelry.

JINGYING: Deconstructing the Ultimate OEM Partner

The name “JINGYING” (精英) translates to “elite” or “essence,” a moniker that reflects its commitment to being the best in its field. It is more than a supplier; it is a partner invested in its clients’ success. Here’s what defines the JINGYING advantage:

1. Core Philosophy: Collaborative Partnership

JINGYING operates on the principle that its success is intrinsically tied to the success of its clients. They view each project not as a simple transaction but as a collaborative venture. Their team of account managers, engineers, and designers works closely with clients to understand their brand identity, target market, and vision. They act as an extension of the client’s own product development team, offering expert advice on design for manufacturability, cost-saving optimizations, and material selection.

2. The Comprehensive OEM Process: A Journey of Precision

JINGYING’s integrated, in-house process ensures quality control at every single stage, from a nebulous idea to a perfectly packaged product.

- Stage 1: Vision and Consultative Design Development. The process begins with a dialogue. Whether a client arrives with detailed tech packs, rough sketches, or just a concept, JINGYING’s experts engage in a thorough consultation. They discuss aesthetics, functionality, target price points, and technical requirements. This stage is crucial for aligning expectations and laying a solid foundation for the project.

- Stage 2: Technical Design and CAD Modeling. This is where creativity is translated into engineering reality. JINGYING’s in-house CAD designers are specialists in jewelry design. They create meticulous 3D digital models that not only capture the aesthetic vision but also preemptively solve manufacturing challenges. They advise on structural integrity, weight distribution for comfort (crucial for necklaces), clasp mechanics, and the most efficient use of material to avoid waste and control costs.

- Stage 3: Rapid Prototyping and Sampling. Once the CAD model is approved, it is sent to JINGYING’s bank of high-resolution 3D printers. A physical prototype is produced in a durable resin or wax-like material. This sample allows the client to hold, feel, try on, and assess the design in real life. They can check the drape of a pendant, the security of a clasp, and the overall proportion. JINGYING facilitates an iterative feedback loop, making adjustments quickly and efficiently until the sample is perfect. This step prevents costly mistakes down the line.

- Stage 4: Mold Making. With the final prototype approved, the technical process of creating production molds begins. A master model is used to craft precise steel molds that will be used in the casting process. The quality of this mold is paramount, as it determines the level of detail captured in every subsequent piece.

- Stage 5: Casting and Formation. The 925 sterling silver is carefully melted and injected into the molds using advanced vacuum casting machines. This vacuum environment is essential for preventing air bubbles and ensuring that every intricate detail of the design is reproduced flawlessly. For chain production, specialized machines stamp, draw, and assemble links with incredible precision.

- Stage 6: Assembly, Soldering, and Stone Setting. This is the domain of highly skilled artisans. Components are meticulously assembled. Laser welders are used for tiny, precise soldering points that are stronger and cleaner than traditional methods. For necklaces adorned with gemstones, setters work under microscopes to claw-set, bezel-set, or pave-set each stone securely and symmetrically.

- Stage 7: Finishing and Polishing – The Art of Transformation. This stage defines the final character and quality of the necklace. JINGYING offers a complete spectrum of finishes:

- High Polish: Achieved with rotating tumblers and hand-polishing with polishing wheels to create a brilliant, reflective mirror shine.

- Matte/Satin Finish: Created using fine abrasives or sandblasting to produce a soft, non-reflective, contemporary look.

- Oxidizing (Antiquing): A chemical process is used to darken the recessed areas of the design, creating contrast and highlighting the details. This is often followed by a light polishing of the raised areas to create a stunning vintage effect.

- Textured Finishes: Using tools or techniques to create unique surfaces like hammered, brushed, or ripple effects.

- Stage 8: Rhodium Plating (Optional). While sterling silver is beautiful in its natural state, many clients opt for a layer of rhodium plating. Rhodium, a platinum-group metal, is applied via electroplating to create an ultra-bright, white, and highly reflective surface that is extremely tarnish-resistant and hypoallergenic.

- Stage 9: Stringent Quality Control (QC). This is the non-negotiable cornerstone of JINGYING’s promise. Every single necklace undergoes a multi-point inspection:

- Hallmark Verification: Ensuring each piece is correctly stamped with “925″ or “Sterling.”

- Dimensional Accuracy: Checking against approved samples and tech specs.

- Surface Perfection: Inspecting for any scratches, pits, polishing marks, or plating inconsistencies.

- Stone and Setting Check: Verifying that all stones are secure, undamaged, and properly aligned.

- Functionality Test: Testing clasps (lobster claws, spring rings, etc.) for security, ease of use, and durability. Checking jump rings for closure and chain for smoothness and avoidable kinks.

- Tarnish Resistance Check: For rhodium-plated pieces, checks are done to ensure a consistent and sufficient layer.

- Stage 10: Custom Packaging and Global Logistics. JINGYING understands that packaging is the first physical touchpoint of a brand with its customer. They offer a full suite of custom packaging options—elegary boxes, branded pouches, gift cards, and certificates of authenticity. Finally, they manage the entire logistics chain, from customs documentation to reliable shipping with trusted partners, ensuring products arrive safely and on time anywhere in the world.

3. Uncompromising Commitment to Ethics and Sustainability

Trust is JINGYING’s most valuable currency. This is built on a foundation of ethical and transparent practices:

- Material Sourcing: They source their sterling silver and gemstones from certified and reputable suppliers who adhere to international standards, ensuring materials are conflict-free and ethically procured.

- Factory Conditions: JINGYING maintains a modern, safe, and professional working environment that complies with international labor standards. They invest in their workforce, believing that a valued and well-trained team produces the best work.

- Environmental Responsibility: They employ responsible waste management systems for metals and chemicals used in the plating and finishing processes, striving to minimize their environmental footprint.

- Transparency: Clients are welcome to visit the factory for audits and to witness the production process firsthand. Virtual meetings and regular production updates are standard practice, ensuring clients are never in the dark.

4. A Universe of Necklace Styles

JINGYING’s expertise encompasses the entire spectrum of necklace design:

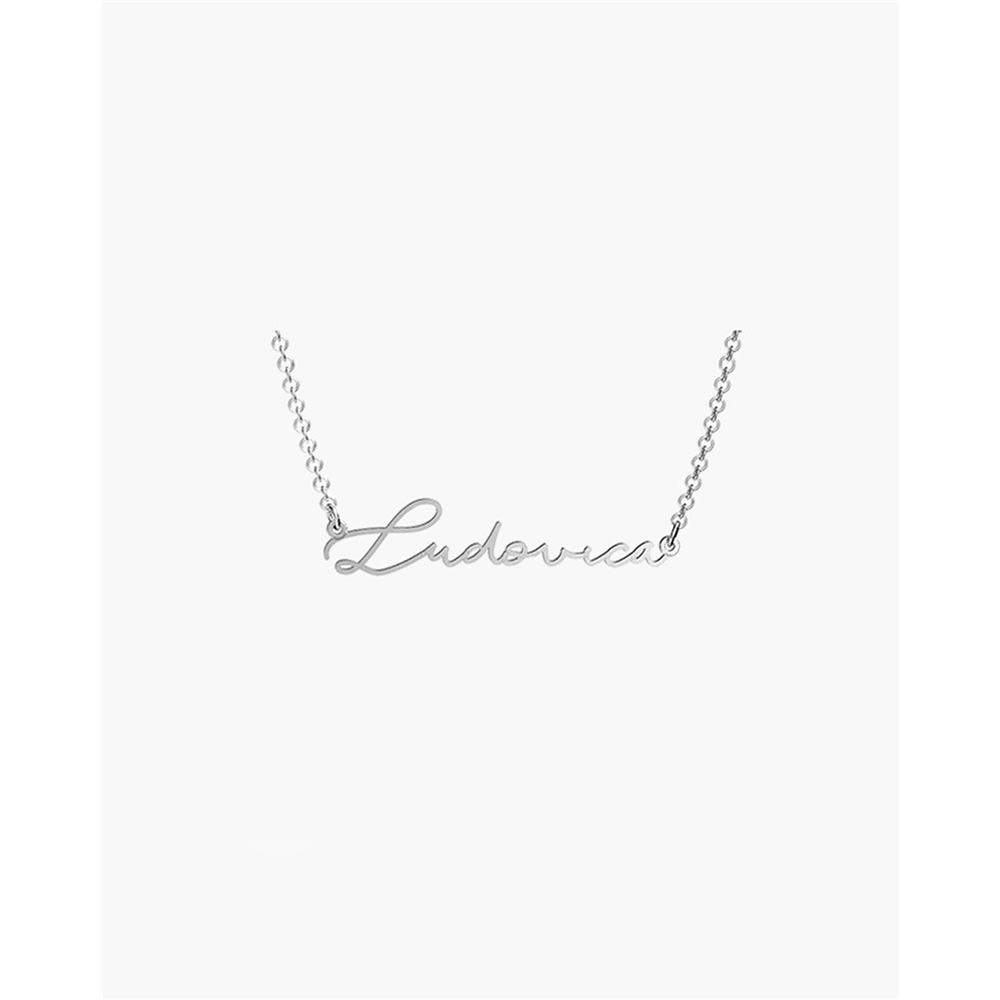

- Pendant Necklaces: Their specialty, ranging from simple solitaire pendants to elaborate custom lockets, initial pendants, and symbolic charms.

- Chains: Producing every classic style, from delicate Cable and Figaro chains to bold Cuban and Rope chains, in any length and width.

- Statement Pieces: Bold, architectural necklaces that serve as the focal point of an outfit.

- Chokers and Collars: Modern and vintage-inspired designs that sit close to the neck.

- Multi-Strand and Layered Necklaces: Complex pieces involving multiple chains or strands, often with mixed pendants.

The JINGYING Difference: Tangible Benefits for Your Brand

Partnering with JINGYING translates into direct competitive advantages:

- Speed and Agility: Rapid prototyping and an efficient supply chain drastically reduce time-to-market, allowing brands to capitalize on trends quickly.

- Unmatched Quality and Consistency: Rigorous QC ensures that every unit that leaves the factory reinforces your brand’s reputation for quality, reducing returns and building customer loyalty.

- Design Innovation and Support: Access to expert CAD designers and engineers helps brands create unique, manufacturable, and stunning designs that stand out in a crowded marketplace.

- Seamless Scalability: JINGYING grows with you, effortlessly handling your evolving needs from launch to global expansion.

- Enhanced Profitability: The exceptional cost-to-quality ratio allows for strong retail markups while offering customers premium products at attractive price points.

Conclusion: Forging Your Brand’s Legacy in Silver

In the demanding world of jewelry retail, the choice of a manufacturing partner is the most critical decision a brand can make. It is a choice that affects product quality, brand reputation, operational efficiency, and ultimately, profitability. JINGYING stands as a beacon of excellence in the OEM manufacturing landscape for 925 sterling silver necklaces. By fusing ancient artisan traditions with cutting-edge technology, embracing a true partnership philosophy, and maintaining an unwavering, obsessive commitment to quality and ethics, JINGYING does not merely supply products; it empowers brands to build legacies. For any business serious about succeeding in the sterling silver jewelry market, JINGYING is not just a option; it is the ultimate destination.