The OEM jewelry manufacturer of Cubic Zirconia Station Bracelet in 18kt Gold Over Sterling

s925 rose gold filled earrings makes custom jewelry supplier

LET’S GET STARTED : mo@kingjy.com

Table of Contents

-

Introduction

-

What Is an OEM Cubic Zirconia Station Bracelet?

-

Why Use 18K Gold Vermeil Over Sterling Silver?

-

Typical OEM Factory Profiles & Capabilities

-

Custom Design & Sample Approval Process

-

Manufacturing Workflow: From Design to Delivery

-

Quality Control Protocols and Certifications

-

Design and Engineering Specifics for Station Bracelets

-

Finishing, Plating, and Stone Setting Techniques

-

Pricing, Lead Times, and MOQ Considerations

-

Common Factory Case Studies

-

Selecting the Right OEM Partner

-

Legal & Compliance: Hallmarks, Materials, and Safety

-

Packaging, Branding, and After‐Sales Support

-

Challenges, Pitfalls, and How to Avoid Them

-

Conclusion and Strategic Recommendations

1. Introduction

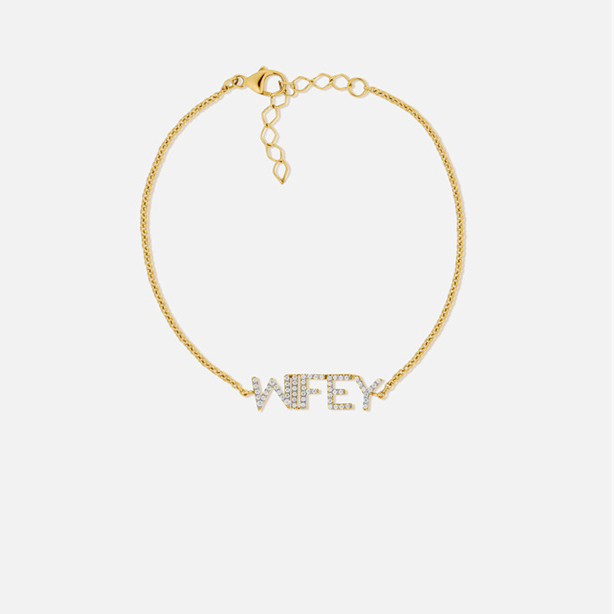

Cubic Zirconia (CZ) station bracelets—featuring individual bezel‑ or prong‑set stones spaced along a delicate chain—are a timeless and universally appealing style. Brands often choose OEM (Original Equipment Manufacturer) partnerships to create these pieces with sterling silver core plated in 18K gold vermeil, balancing cost, visual luxury, and marketability. This article examines how OEM operations produce such bracelets at scale, what goes into the process, and how brands or buyers can best partner for success.

2. What Is an OEM Cubic Zirconia Station Bracelet?

-

“Station bracelet” refers to a design where individual stones (in bezels or settings) are fixed at intervals along a chain.

-

In this context, each station typically holds a high‑grade AAA round CZ, set into sterling silver (925) components.

-

The silver is then plated to 18K yellow gold, known as type of vermeil—with minimum plating thickness standards (often ~2–3 microns).

-

OEM suppliers provide full turnkey production based on client designs—multiple stones spaced on a chain with clasp, logo, and finishing.

3. Why Use 18K Gold Vermeil Over Sterling Silver?

-

Affordability: Sterling silver is much cheaper than solid gold. 18K gold vermeil offers the same look at a lower cost.

-

Luxurious appearance: A warm yellow tone with rich finish. Quality plating can last up to a year or more with proper care chingying-jewelry.com+12eshinejewelry.com+12JINGYING JEWELRY+12longlong-jewelry.en.made-in-china.comReddit.

-

Regulatory & hallmark advantages: Buyers can legally stamp “925” plus a gold mark or hallmark.

-

CZ complements plating: High brilliance of cubic zirconia contrasts attractively with polished gold surface.

4. Typical OEM Factory Profiles & Capabilities

Many factories in Guangzhou and Panyu specialize in custom CZ jewelry OEM/ODM; common names include:

-

JingYing Jewelry: Established 1998, capacity 50k–100k pieces a month, provides original design service, CNC mold creation, hand‑setting, double plating (silver base then 18K), and rigorous QC process longlong-jewelry.en.made-in-china.com+2chingying-jewelry.com+2chingying-jewelry.com+2.

-

Eshine Jewelry Co., Ltd.: SGS certified, Sedex audited, experienced in 18K gilt bezel‑set CZ station necklace/bracelet sets => deliver turnkey OEM services including free sampling, one‑stop solution, cost savings up to 40% eshinejewelry.com.

-

Yin Fu Jewelry / Longlong Jewelry: Factories offering both silver and brass-based OEM, plating options in yellow/rose gold, strong QC, and flexible MOQs alibaba.com+5longlong-jewelry.en.made-in-china.com+5made-in-china.com+5.

These factories support OEM/ODM, meaning they can either follow your specific design or help you co‑design styles.

5. Custom Design & Sample Approval Process

Step 1: Idea or Sample Submission

-

Provide a sketch, technical visual, or existing sample.

-

Communicate desired chain length (e.g. 7″+1″ extender), stone size (e.g. 3 mm, 4 mm CZ), and spacing.

Step 2: 3D Modeling & Mold Creation

-

Factory designers create 3D CAD and metal master molds using CNC machining to guarantee smooth cast surfaces and accurate dimensions eshinejewelry.comchingying-jewelry.com+1chingying-jewelry.com+1.

Step 3: Sample Production

-

A prototype or sample is cast, polished, set with stones, plated, and delivered — often within 7 days longlong-jewelry.en.made-in-china.comchingying-jewelry.com.

Step 4: Evaluation

-

Buyer checks style, plating color/thickness, stone clarity/cut.

-

Adjustments requested (e.g. plating thickness, chain gauge, setting style).

After approval, large‑scale production begins.

6. Manufacturing Workflow: From Design to Delivery

-

Wax Casting or Modern Casting: Using inwested shells, molten sterling silver is poured or laser-sintered using 3D printed patterns.

-

Cleaning & Polishing: Manual trimming, tumbling, and polishing produce a smooth finish.

-

Stone Setting: Factories often use Japanese micro-inlay machines for 5A-grade CZ mounting for high precision and retention chingying-jewelry.com+1chingying-jewelry.com+1.

-

Double Plating Process: First silver plating to smooth base, then 2–3 micron 18K gold vermeil plating to meet longevity standards chingying-jewelry.com+1chingying-jewelry.com+1.

-

Final QC: Includes drop‐tests (e.g. 3 m drop for loose‑stone check), steel‐needle tap test, plating thickness measurement, visual inspection chingying-jewelry.com+1chingying-jewelry.com+1.

-

Packaging & Shipping: Individual poly‑bags or branded packaging; shipped by DHL/UPS/TT, factory offers repair windows (e.g. 3–6 months) chingying-jewelry.com+1chingying-jewelry.com+1.

7. Quality Control Protocols and Certifications

-

SGS and REACH compliance: many factories hold third‑party certifications for metals and plating eshinejewelry.comlonglong-jewelry.en.made-in-china.com.

-

Stone retention tests: tapping stones with steel needle and dropping assembled bracelet from ~3 m.

-

Plating thickness measurement report on gold layer.

-

Surface finish test: manual rub tests to check for discoloration, wear, or plating flaws.

-

Batch sampling: QC engineers inspect random pieces from each batch before shipping chingying-jewelry.com.

8. Design and Engineering Specifics for Station Bracelets

-

Chain Gauge: typically fine cable chains (~0.8–1.2 mm thickness) balance strength and elegance.

-

Setting Type: bezel‑set gives a sleek seamless look; prong or scalloped bezel is also common.

-

Stone Size & Spacing: typical CZ stations are 3–5 mm stones spaced equally, sometimes alternating sizes.

-

Clasp Style: lobster or spring‑ring clasp loops are soldered or cast from silver.

-

Extender Links: usually include 1 inch metal links allowing adjustable fit.

-

Hallmarks: “925” plus “18K GP” or shortened notation ensures compliance.

9. Finishing, Plating, and Stone Setting Techniques

a) Stone Quality

-

Factories offer AAA or 5A CZ: high brilliance and clarity with consistent cut quality.

b) Bezel Setting

-

Machine‑precise setting methods (micro‑inlay) reduce the risk of loose stones.

c) Polishing

-

Multi‑step polishing: tumbling, buffing, final hand polish to achieve glossy, scratch‑free surfaces.

d) Gold Vermeil Plating

-

Most reputable OEMs use 2-step plating: silver plating base → 18K gold final. Gold thickness often 2–3 microns to meet vermeil standard and durability up to ~12 months with normal wear chingying-jewelry.comchingying-jewelry.com.

e) Post‑plating QC

-

Visual uniformity of plating, no spots or bare edges.

-

Stone appearance check: no flooding of bezel, proper alignment.

10. Pricing, Lead Times, and MOQ Considerations

-

Sample Fee: many OEMs offer free samples or very low cost, depending on complexity and stone count.

-

MOQ (Minimum Order Quantity): often around 30 to 50 pieces per design for sterling/ gold plated; brass prototypes may have higher minimums longlong-jewelry.en.made-in-china.commade-in-china.com.

-

Lead Time: sample turnaround 7–10 days; full production 20–30 days depending on volume and tooling.

-

Pricing: typical ex‑factory cost is $20–$40 per piece (depending on stone size/number, chain thickness) for a 7″ station bracelet with 4–6 CZ stones.

11. Common Factory Case Studies

JingYing Jewelry

-

Produces CZ bracelets in sterling silver and 18K plating with CNC mold, micro inlay setting, double plating, QC team, monthly capacity up to 50,000 pcs JINGYING JEWELRY+2chingying-jewelry.com+2chingying-jewelry.com+2.

Eshine Jewelry Co.

-

Offers classic station bracelet sets (necklace + bracelet) in cable chain with bezel CZ stations; touts SGS certification and Sedex audit, OEM sampling, one‑stop services eshinejewelry.com.

Longlong Jewelry / Yin Fu

-

Accept both silver and brass cores, plating options (yellow gold, rose gold, rhodium), flexible MOQs (silver ~30pcs/design, brass ~100) longlong-jewelry.en.made-in-china.commade-in-china.com.

12. Selecting the Right OEM Partner

When evaluating suppliers, consider:

-

Design flexibility: Can they accommodate your specific layout, stone size, spacing, extender length?

-

Sample & 3D support: Fast CAD and sample delivery to iterate ahead of big orders.

-

Stone quality: AAA/5A CZ with consistent sparkle and color.

-

Gold plating thickness: Vermeil standard 2–3 μm or more for durability.

-

QC processes: drop tests, plating checks, stone retention tests.

-

Certifications: SGS, REACH, Sedex are pluses.

-

Communication clarity: timeline, logistics, packaging, lead time.

-

After‑sales service: warranty, repair policy (e.g., replacements if stones fall out).

13. Legal & Compliance: Hallmarks, Materials, and Safety

-

Bracelets made with sterling silver must bear a “925” hallmark; plating should be certified as 18K gold vermeil.

-

CZ stones are non‑regulated but must be clearly labeled in packaging or product descriptions.

-

Surface finishing and plating chemicals need to comply with EU REACH and other international standards eshinejewelry.comlonglong-jewelry.en.made-in-china.com.

-

Packaging disclaimers and country of origin labeling may be required depending on destination market.

14. Packaging, Branding, and After‑Sales Support

-

OEM factories typically offer blank packaging or optional custom branding (e.g. printed box, logo polishing cloth).

-

They can include QC reports, plating thickness certificates, and styling cards.

-

Many factories offer a repair window (e.g. replacement of lost CZ or replating) for 3 to 6 months after delivery chingying-jewelry.comlonglong-jewelry.en.made-in-china.com.

15. Challenges, Pitfalls, and How to Avoid Them

a) Plating wear-off too fast

-

Avoid cheap plating (<1 µm). Specify 2–3 µm gold plating and request sample aging test.

b) Loose stones after shipping

-

Ensure supplier does tapping/drop tests. Seek micro-inlay/laser‑setting methods.

c) Color mismatch of gold plating

-

Request sample and compare to your reference gold tone; adjust plating bath if needed.

d) Mis-aligned stations or chain inconsistency

-

Insist on CNC molds and steel mandrel finishing, verify chain gauge/spec.

e) Low MOQ but poor quality

-

Some suppliers quote low MOQ (e.g. 5‑10 pcs), but quality may be inconsistent. Prefer 30+ MOQ from proven factories.

f) Communication delays when overseas

-

Choose suppliers with English‑fluent contacts, responsive support, clear timelines.

16. Conclusion and Strategic Recommendations

An 18K gold over sterling silver cubic zirconia station bracelet is a beautiful, accessible luxury product ideally suited to OEM manufacturing. With specialized factories like JingYing, Eshine, Longlong, and Yin Fu—all based in Guangzhou/Panyu—brands can achieve high-quality design, plating, stone-setting, and QC with reasonable investment and lead time.

To launch such a product successfully:

-

Begin with a clear spec sheet (chain gauge, CZ size/type, spacing, clasp style, plating thickness).

-

Request CAD renders and physical prototypes to vet appearance and plating tone.

-

Choose manufacturers with proven QC standards—drop tests, plating reports, antisuturing of stones.

-

Balance MOQ and cost efficiency, ensuring batch production quality matches your brand vision.

-

Negotiate after-sales support or warranty in case stones loosen or plating wears prematurely.

By carefully selecting and managing the OEM partner, you can bring to market a luxurious, well-crafted CZ station bracelet that meets both brand standards and consumer expectations. Let me know if you’d like help drafting an inquiry template, sourcing sample quotes, or comparison of factories based on your exact design requirements.