Professional OEM Pearl Earring Manufacturing: A Complete Guide

OEM/ODM jewelry manufacturer design custom your own jewelry

LET’S GET STARTED : mo@kingjy.com

Professional OEM Pearl Earring Manufacturing: A Complete Guide

Introduction

The global pearl jewelry market is projected to reach $15.2 billion by 2027, with pearl earrings being one of the most popular categories. For jewelry brands looking to enter this lucrative market, partnering with a professional OEM (Original Equipment Manufacturer) pearl earring factory is essential for producing high-quality, cost-effective designs.

This 5,000-word guide provides an in-depth look at:

- Overview of Pearl Earring OEM Manufacturing

- Types of Pearls Used in Production

- Materials & Components Breakdown

- Manufacturing Process Step-by-Step

- Quality Control Standards

- Customization Options

- Cost Structure for Bulk Orders

- How to Select the Right OEM Partner

- Current Market Trends

- Sustainability in Pearl Farming & Production

1. Overview of Pearl Earring OEM Manufacturing

What is a Pearl Earring OEM Factory?

An OEM factory specializes in producing pearl earrings according to a brand’s specifications, handling:

- Design development

- Material sourcing

- Production

- Quality control

- Packaging

Key Benefits of OEM Production

- Cost efficiency through bulk manufacturing

- Custom designs tailored to your brand

- Quality assurance with professional craftsmanship

- Faster turnaround vs. in-house production

- Private labeling for brand identity

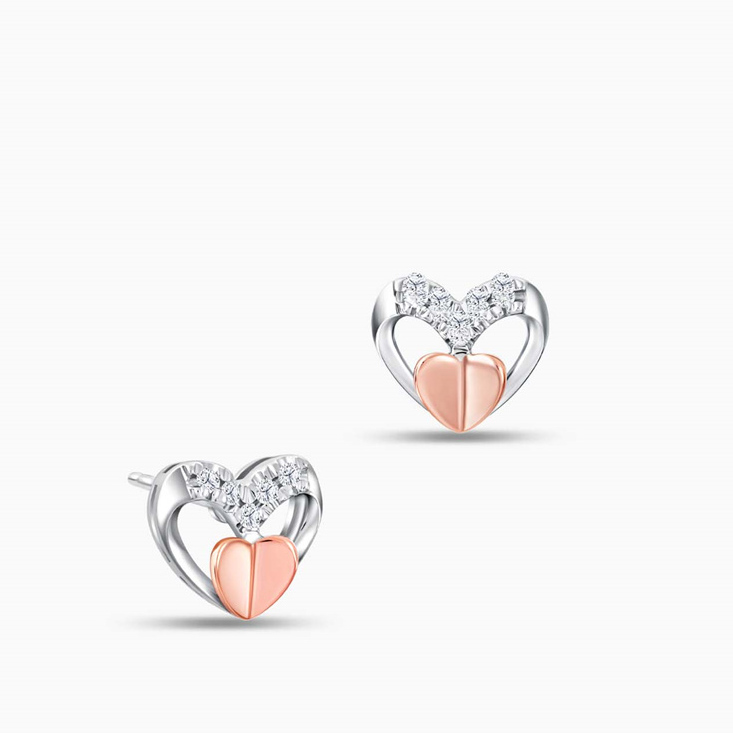

Common Pearl Earring Styles Produced

| Style | Description |

|---|---|

| Stud Earrings | Classic single pearl design |

| Dangle Earrings | Pearls suspended from chains |

| Hoop Earrings | Pearls set along hoop frames |

| Cluster Earrings | Multiple pearls in one setting |

| Jacket Earrings | Pearl with decorative metal surrounds |

2. Types of Pearls Used in Production

A. Natural Pearls

- Saltwater Pearls (Akoya, South Sea, Tahitian)

- Higher luster, more expensive

- Limited availability

- Freshwater Pearls

- More affordable

- Wide variety of shapes/colors

B. Cultured Pearls

- Bead-Nucleated (Rounder shape)

- Tissue-Nucleated (More irregular)

- Keshi Pearls (No nucleus, all nacre)

C. Imitation Pearls

- Glass Pearls (Coated with pearl essence)

- Plastic Pearls (Most affordable option)

- Shell Pearls (Made from crushed mollusk shells)

Comparison Table: Pearl Types & Characteristics

| Pearl Type | Cost (per pearl) | Durability | Luster |

|---|---|---|---|

| Natural Saltwater | $50-$500+ | High | Excellent |

| Cultured Freshwater | $5-$50 | Good | Very Good |

| Imitation | $0.10-$5 | Fair | Good |

3. Materials & Components Breakdown

A. Metal Components

- Posts & Backs

- Surgical steel ($0.05-$0.20)

- Sterling silver ($0.30-$1.00)

- 14K gold ($3-$10)

- Earring Settings

- Prong settings

- Bezel settings

- French hooks

- Leverbacks

B. Additional Materials

- Adhesives (Epoxy resin for secure setting)

- Enamel (For colored accents)

- Rhodium plating (For tarnish resistance)

4. Manufacturing Process Step-by-Step

Stage 1: Design & Prototyping

- CAD design development

- 3D printing of prototypes

- Sample approval process

Stage 2: Pearl Preparation

- Sorting by size, shape, color

- Drilling holes (if needed)

- Quality grading

Stage 3: Metal Work

- Casting or stamping components

- Polishing and finishing

- Plating (if applicable)

Stage 4: Assembly

- Pearl setting (gluing or mechanical)

- Quality inspection

- Final polishing

Stage 5: Packaging

- Individual poly bags

- Branded boxes

- Certificates of authenticity

5. Quality Control Standards

Pearl Quality Checks

- Luster evaluation

- Surface perfection grading

- Shape consistency

- Color matching

Metal Quality Tests

- Purity verification (XRF testing)

- Nickel content testing

- Plating thickness measurement

Final Product Inspection

- Security of settings

- Post straightness

- Overall aesthetic appeal

6. Customization Options

Design Customizations

- Pearl size (3mm to 12mm common)

- Metal type and color

- Engraving options

- Unique settings

Branding Opportunities

- Custom packaging

- Logo engraving

- Unique clasp designs

- Signature color schemes

7. Cost Structure for Bulk Orders

Sample Pricing for 10,000 Pairs

| Component | Cost Range |

|---|---|

| Freshwater Pearls (6mm) | $8,000-$15,000 |

| Sterling Silver Settings | $5,000-$12,000 |

| Labor (China-based) | $3,000-$8,000 |

| Packaging | $1,000-$5,000 |

| Quality Control | $500-$2,000 |

| Shipping | $1,500-$4,000 |

| Total Estimate | $19,000-$46,000 |

*Cost per pair: $1.90-$4.60*

8. Selecting the Right OEM Partner

Key Selection Criteria

- Pearl sourcing network

- Metalworking capabilities

- Minimum order quantities

- Quality certifications

- Design support services

Top Manufacturing Regions

- China (Qingdao, Zhuji)

- Japan (Mie Prefecture)

- Thailand (Bangkok)

- India (Hyderabad)

9. Current Market Trends

Popular Styles for 2024-2025

- Mini pearl studs (3-5mm)

- Pearl huggies (small hoop styles)

- Asymmetric designs

- Mixed metal combinations

- Baroque pearl earrings

Consumer Preferences

- Sustainable sourcing

- Hypoallergenic materials

- Customizable options

- Affordable luxury

10. Sustainability in Pearl Production

Ethical Farming Practices

- Non-nucleated pearl cultivation

- Chemical-free farming

- Ecosystem protection

Eco-Friendly Manufacturing

- Recycled metals

- Biodegradable packaging

- Water conservation processes

Conclusion

Partnering with a professional pearl earring OEM manufacturer provides brands with:

- High-quality production

- Cost-effective solutions

- Design flexibility

- Market-ready products

The pearl jewelry market continues to grow, with opportunities for brands that can offer unique designs at competitive prices through strategic OEM partnerships.