Unveiling the Complete OEM Jewelry Production Process: 18 Steps from Design to Delivery

Introduction

The jewelry OEM (Original Equipment Manufacturing) industry is a highly specialized field that combines artistry, precision engineering, and stringent quality control. From initial design sketches to final shipment, each step must meet exacting standards, especially when producing for luxury brands. This article provides an in-depth look at the 18 critical stages of jewelry OEM production, covering design, manufacturing, and quality assurance.

Part 1: Design Phase – Where Creativity Meets Precision

1. Client Consultation & Sketch Submission

The process begins when a client (brand or retailer) provides a design concept, either as hand-drawn sketches or digital files. Luxury brands often require strict non-disclosure agreements (NDAs) before sharing any design details.

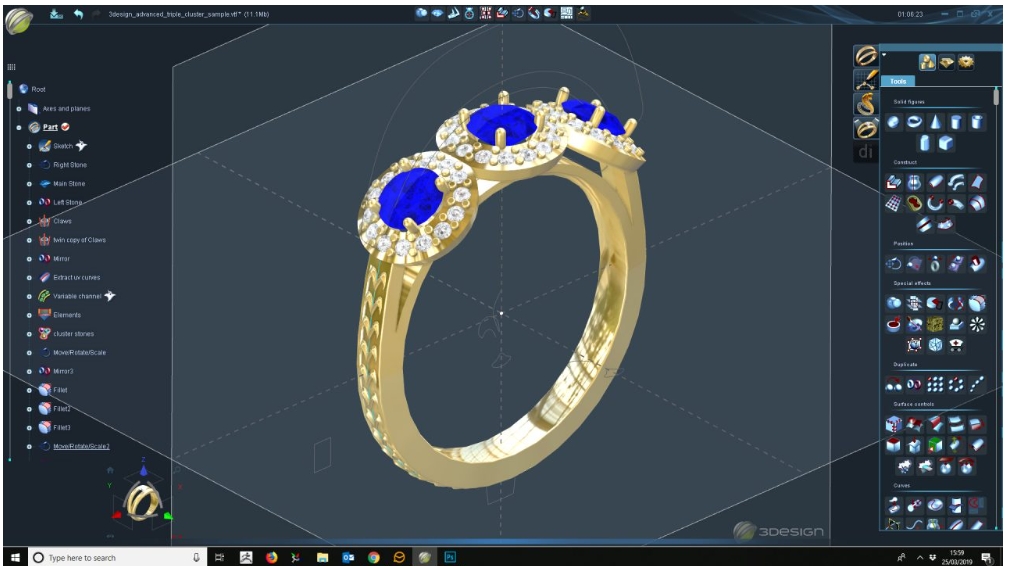

2. Digital Modeling with JewelCAD

Designers use JewelCAD, a leading jewelry design software, to create a 3D model. This stage ensures:

- Accurate proportions and dimensions

- Structural feasibility for casting and stone setting

- Adjustments based on client feedback

3. 3D Wax Printing (±0.05mm Precision)

The approved digital model is 3D-printed in wax using high-resolution stereolithography (SLA) or multi-jet modeling (MJM). The tolerance is kept within ±0.05mm to ensure intricate details are preserved.

4. Client Approval & Design Encryption

Before moving to production, the 3D model is shared with the client via encrypted files to prevent intellectual property theft—common practice when working with international luxury brands.

Part 2: Production Phase – Crafting Perfection

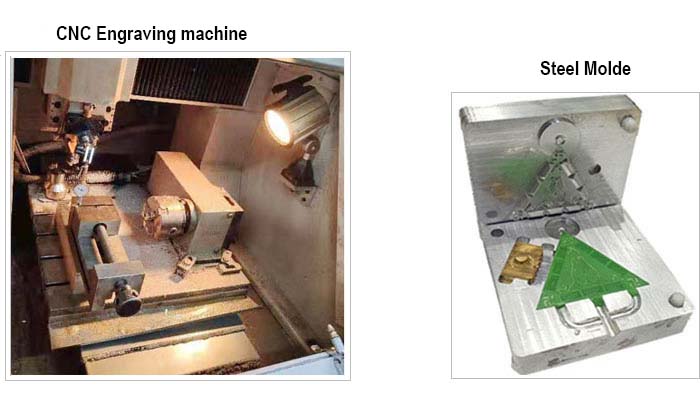

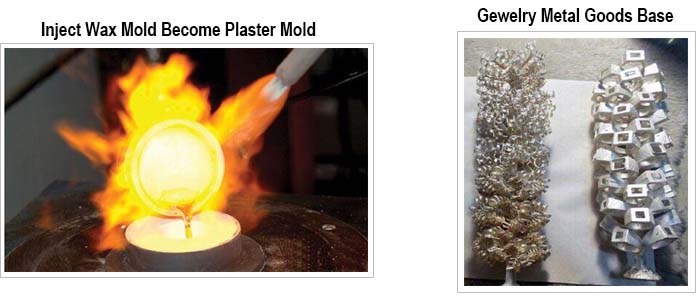

5. Rubber Mold Making (for Mass Production)

For bulk orders, a rubber mold is created from the master wax model. This allows for consistent wax pattern duplication.

6. Investment Casting (Lost-Wax Technique)

- Wax trees are assembled and encased in a ceramic shell.

- Molten metal (gold, silver, platinum) is poured into the mold.

- After cooling, the ceramic is broken away, revealing raw metal pieces.

7. Deburring & Polishing

Excess metal (sprues) is removed, and surfaces are polished to a smooth finish using:

- Tumbling machines (for initial smoothing)

- Hand polishing (for precision edges)

8. Cyanide-Free Electroplating (0.03μm Accuracy)

To meet eco-friendly and EU compliance standards, cyanide-free electroplating is applied. The gold or rhodium layer is controlled to 0.03μm for consistent color and durability.

9. Micro-Pave Setting (80 Stones/cm²)

For high-end jewelry, micro-pave setting is used, allowing up to 80 diamonds or gemstones per square centimeter. This requires:

- Laser-guided precision for drilling

- Microscopic inspection to ensure stone alignment

10. Laser Engraving & Hallmarking

- Laser engraving adds serial numbers or logos.

- Hallmarks (e.g., “750″ for 18K gold) are stamped for authenticity.

11. Assembly (for Multi-Part Designs)

Complex pieces (e.g., clasps, hinges) are assembled manually or with micro-welding tools.

Part 3: Quality Control – Ensuring Excellence

12. XRF Spectrometer Testing (≤0.3% Error)

An X-ray fluorescence (XRF) spectrometer verifies metal purity, detecting alloy composition with ≤0.3% error.

13. Gemstone Verification

- Diamond testers check authenticity.

- Microscopes inspect for inclusions or damage.

14. 48-Hour Salt Spray Test (Corrosion Resistance)

To simulate extreme environments, jewelry undergoes a 48-hour salt spray test, ensuring:

- No tarnishing or peeling of plating

- Structural integrity under humidity

15. Weight & Dimension Check

Each piece is weighed and measured against specifications to ensure consistency.

16. Final Visual Inspection

Trained QC specialists examine:

- Surface scratches

- Stone tightness

- Overall aesthetic quality

Part 4: Packaging & Shipping

17. Anti-Tarnish Packaging

Jewelry is sealed in anti-tarnish bags with silica gel to prevent oxidation during transit.

18. Logistics & Customs Compliance

- Luxury brands may require secure couriers (e.g., Brinks).

- Proper documentation (e.g., Kimberley Process Certificates for diamonds) is prepared.

Conclusion

The OEM jewelry production process is a meticulous blend of artistry, engineering, and technology. From ±0.05mm 3D wax printing to 80-stone micro-pave settings, each stage demands precision. With XRF testing and 48-hour salt spray checks, manufacturers ensure only flawless pieces reach consumers.

For brands seeking OEM partners, understanding these 18 critical steps ensures they select a supplier capable of meeting high-end jewelry standards.