This document provides a detailed analysis of JINGYING Company’s comprehensive capabilities as a manufacturing partner, specifically tailored to support a client’s strategic initiative to launch a branded product line. The report is structured to address the client’s specific inquiries regarding Original Design Manufacturing (ODM) and Original Equipment Manufacturing (OEM) services. It delves into the product categories supported under each model, outlines Minimum Order Quantities (MOQs), elaborates on the spectrum of customization options, details typical lead times, and clarifies the requirements for OEM development projects. The overarching aim is to furnish the client with the necessary information to make an informed partnership decision, aligning with their phased strategy of commencing with ODM products for market testing and progressively transitioning to OEM production for scaled volumes and proprietary designs.

1. Introduction: Navigating the ODM and OEM Landscape with JINGYING

In the dynamic global marketplace, the choice of a manufacturing partner is a pivotal strategic decision that directly impacts product quality, supply chain resilience, brand identity, and market success. For brands looking to develop or expand a product line without bearing the full burden of in-house manufacturing infrastructure, partnering with a capable and flexible contract manufacturer is paramount. JINGYING Company positions itself as a holistic solution provider, bridging the gap between conceptual design and finished goods through its robust ODM and OEM services.

The client’s strategy—initiating market entry with customized ODM products before investing in fully custom OEM production—is a prudent and widely adopted approach. It allows for brand establishment, market response testing, and inventory risk minimization before committing to the higher investment and longer timelines associated with custom design and tooling. JINGYING is uniquely equipped to support this entire journey, offering a seamless pathway from ODM to OEM within a single partnership. This document serves as a foundational guide to our capabilities, structured to answer the client’s specific questions with clarity and depth.

2. Product Categories: ODM vs. OEM Support

JINGYING’s manufacturing expertise spans several key consumer and industrial product categories. Our support structure for ODM and OEM varies slightly based on the inherent design ownership and complexity.

2.1 ODM-Supported Categories

Our ODM portfolio consists of our proprietary, in-house designed products that have been market-validated for functionality, quality, and appeal. These are “catalog” items available for brand customization. Key categories include:

- Consumer Electronics: This encompasses a wide range such as Bluetooth headphones and earbuds, portable speakers, power banks, USB cables and adapters, basic smart home devices (like plugs and sensors), and tablet/phone accessories (cases, stands, styluses).

- Home and Kitchen Appliances: Items like compact air purifiers, humidifiers, electric kettles, blenders, food scales, and LED desk/floor lamps.

- Lifestyle and Travel Products: Including luggage tags, travel pillows, water bottles, eco-friendly shopping bags, and basic organizers.

- Outdoor and Leisure: Such as compact binoculars, LED flashlights, portable camping lights, and simple fitness accessories (resistance bands, yoga mats).

For ODM, the core product design, engineering, and initial safety certifications are owned and provided by JINGYING. The client selects from this existing portfolio.

2.2 OEM-Supported Categories

OEM services are offered across a broader and potentially more complex set of categories, as they are driven by the client’s specifications. We can manufacture custom designs in all the categories listed above and additionally in areas requiring deeper technical collaboration:

- Advanced Consumer Electronics: Custom-designed audio equipment, specialized smart home hubs, unique wearable technology, and proprietary charging solutions.

- Telecommunications Equipment: Routers, network switches, and other hardware based on provided chipset and architecture specs.

- Industrial Design-Intensive Products: Ergonomic tools, specialized medical device enclosures (non-active components), custom point-of-sale systems, and tailored automotive accessories.

- Complex Plastic and Metal Fabrications: Products requiring unique molds for intricate parts, multi-material assemblies, or specific metal finishes and treatments.

The distinction is not in the category per se, but in the origin of the design. Essentially, if a product concept can be clearly specified, JINGYING can evaluate its manufacturability and provide an OEM proposal.

3. Minimum Order Quantities (MOQs)

MOQs are critical for production feasibility and cost-effectiveness. JINGYING employs a flexible MOQ structure to accommodate both startups and established brands.

3.1 ODM MOQs

ODM MOQs are generally lower, as they leverage existing molds, material supply chains, and assembly lines.

- Standard MOQ: Ranges from 500 to 1,000 units per SKU (e.g., per specific product model/color variant). This applies to most electronics and appliances.

- Low-Volume Options: For simpler items like cables, basic cases, or fabric-based products, MOQs can start as low as 300 units.

- Factors Influencing MOQ: The final MOQ for an ODM order can be influenced by the extent of customization. A simple logo print may keep the MOQ at 500, while a unique color requiring a special paint batch or custom packaging might increase the MOQ to 1,500 units to be economically viable.

3.2 OEM MOQs

OEM MOQs are significantly higher due to the substantial upfront investments required.

- Standard MOQ: Typically starts at 5,000 to 10,000 units per SKU for the first production run. This is necessary to amortize the costs of custom mold creation (which can range from $10,000 to $50,000+ per mold), specialized tooling, comprehensive factory setup, and rigorous prototype testing.

- Flexibility for Growth: We understand the client’s phased plan. For the transition of a successful ODM SKU to a redesigned OEM version, we can sometimes negotiate a lower initial MOQ (e.g., 3,000 units) based on the proven market demand and our existing relationship. However, for a completely new, from-scratch OEM design, the 5,000-10,000 unit threshold is standard.

- Component MOQs: It’s important to note that custom components (like a uniquely shaped battery or a proprietary display) from our sub-suppliers may carry their own high MOQs, which can affect the overall project MOQ.

4. Customization Options: From Branding to Full Design Realization

4.1 ODM Customization (Brand-Centric)

ODM customization focuses on applying the client’s brand identity to an existing JINGYING product.

- Logo Application: Techniques include silk-screen printing, laser etching, hot stamping, or debossing on the product housing. For packaging, high-quality offset printing is standard.

- Color Customization: Offering Pantone (PMS) color matching for plastic injection parts, paint finishes, or fabric elements. Note: Significant color changes may incur a fee for masterbatch preparation.

- Packaging and Literature: Full customization of retail boxes, blister packs, user manuals, warranty cards, and stickers to align with brand guidelines. We handle graphic design support or work with client-provided print-ready artwork.

- Pre-installed Software/Settings: For electronic products, we can pre-load custom firmware, default language settings, branded wallpapers, or pre-pair Bluetooth devices.

- Accessory Variations: Options to include or exclude specific cables, adapters, or cases within the package.

4.2 OEM Customization (Design-Centric)

OEM customization is essentially limitless, bound only by engineering feasibility, safety regulations, and budget. It involves:

- Industrial Design Realization: Translating client-provided 3D CAD models, sketches, or concepts into a manufacturable product.

- Material Specification: Sourcing and utilizing specific grades of plastic (e.g., ABS, PC), metals (aluminum, stainless steel), composites, or fabrics as per the Bill of Materials (BOM).

- Full Mechanical and Electrical Engineering: Designing internal layouts, PCBAs (Printed Circuit Board Assemblies), selecting and integrating components (chips, sensors, batteries), and ensuring thermal and mechanical integrity.

- Software and Firmware Development: Collaborating with the client’s tech team or our partners to develop fully custom firmware/software.

- Comprehensive Certification Management: Guiding the product through necessary certification processes (e.g., FCC, CE, UL, RoHS, Bluetooth SIG) based on target markets.

- End-to-End Packaging Design: Creating structural and graphic packaging from the ground up.

5. Typical Lead Times

Lead times are calculated from the date of final approval and deposit receipt.

5.1 ODM Lead Times

- Standard Production: 30-45 days for items with standard color/logo customization.

- Extended Timeline: 45-60 days if custom packaging is involved (due to design proofing and printing cycles) or if special materials/components are required.

- Sample Lead Time: 7-10 working days for providing pre-production samples after customization details are confirmed.

5.2 OEM Lead Times

OEM timelines are project-based and considerably longer due to the development phase.

- Development and Prototyping Phase: 60-90 days. This includes engineering review, DFM (Design for Manufacturability) analysis, prototype tooling, and 1-3 rounds of prototype sampling and testing.

- Mass Production (Post-Tooling): 45-60 days after final prototype approval and completion of production mold fabrication. This covers raw material procurement, production line setup, pilot runs, and full batch assembly.

- Total Timeline: Clients should anticipate a total timeline of 4 to 6 months from project kick-off to finished goods ready for shipment for a standard OEM project.

6. Requirements and Process for OEM Development

A successful OEM project requires clear inputs, structured collaboration, and upfront investment.

6.1 Client-Provided Requirements for OEM

- Detailed Product Specifications: A comprehensive document covering target market, intended use, functional requirements, performance criteria (e.g., battery life, output power), and physical dimensions.

- Design Files: Preferably 3D CAD models (STEP, IGES formats) and 2D engineering drawings with tolerances. Industrial design renderings are also valuable.

- Bill of Materials (BOM): A preliminary list of preferred or required key components, especially for critical items like ICs, displays, or batteries.

- Regulatory and Compliance Targets: A list of mandatory certifications for the intended sales regions.

- Budget and Volume Expectations: Clear communication on target FOB cost and forecasted annual volumes to guide material and process selection.

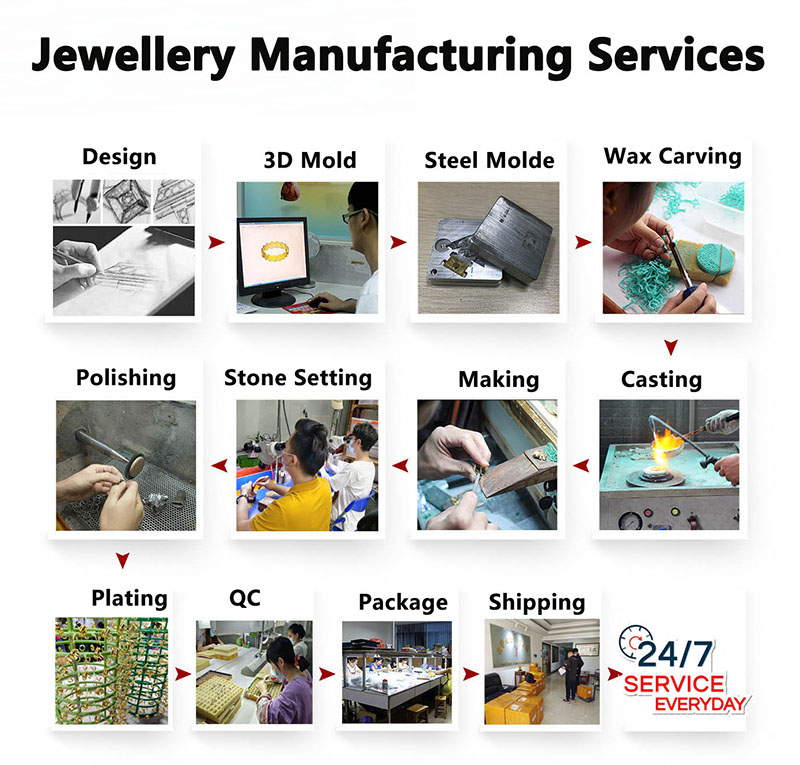

6.2 JINGYING’s OEM Development Process

- NDA and Project Kick-off: Execution of a mutual Non-Disclosure Agreement (NDA) followed by a deep-dive meeting to align on all requirements.

- Feasibility Study and Quotation: Our engineering team conducts a DFM analysis, sources component quotations, and provides a detailed project timeline and cost breakdown (including NRE – Non-Recurring Engineering – costs for molds and tooling).

- Development Agreement: Signing of a contract outlining phases, costs, responsibilities, and IP ownership.

- Prototyping: Creation of functional prototypes (often using rapid prototyping techniques like SLA or 3D printing initially, followed by T1 samples from soft tooling or initial mold trials).

- Testing and Iteration: Rigorous in-house and third-party testing (if needed). Client evaluates and provides feedback for refinements.

- Pre-production and Mass Production: Final mold creation, pilot run of 50-200 units for final verification, followed by full mass production.

- Quality Assurance and Delivery: Strict QC inspection (AQL sampling), packing, and arrangement of shipping.

7. Conclusion: A Strategic Partnership for Scalable Growth

JINGYING Company offers a vertically integrated, transparent, and scalable manufacturing partnership perfectly aligned with the client’s strategic roadmap. Our strength lies in providing a clear, supported pathway—from launching quickly and cost-effectively with our customizable ODM portfolio, to building a unique, proprietary product line through our comprehensive OEM services.

We recommend beginning the engagement with a focused discussion on the specific ODM products of interest for the initial test phase. Concurrently, we can initiate preliminary conversations about the long-term OEM vision. This parallel approach will maximize efficiency and ensure a smooth transition when the time is right.

We are prepared to provide catalogs, ODM samples, and detailed quotations for the next steps. JINGYING looks forward to the opportunity to become your trusted manufacturing partner, contributing to the success and growth of your brand.