JINGYING will show you the process of silver jewelry customization from CAD design to the products.

Silver jewelry customization is a complex and delicate process. From design sketch to final product, it needs to go through multiple steps and links. The following is the detailed steps of silver jewelry customization:

I. Design stage

1. Customer demand communication:

- Communicate with customers in detail to understand their needs and preferences, including style, material, budget, etc.

- Collect relevant information and reference materials to provide a basis for design.

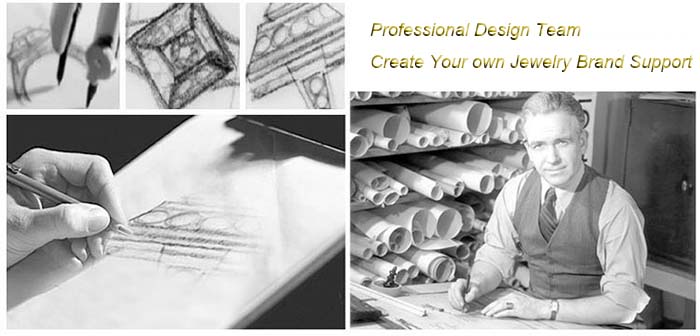

2. Design sketch drawing:

- According to customer needs, designers make preliminary design ideas and draw design sketches.

- Sketches usually include the overall shape of the jewelry, detailed design, and views from various angles.

3. Design plan confirmation:

- Present the design sketch to the customer and listen to the customer’s feedback and opinions.

- Modify and improve according to the customer’s feedback until the customer is satisfied and confirms the design plan.

II. Production stage

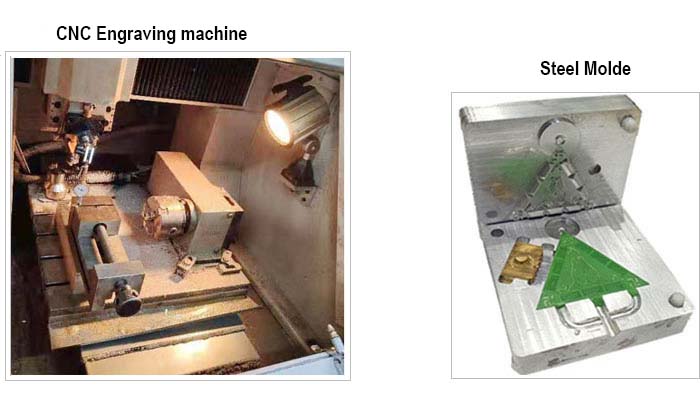

1. Make wax mold:

- Make a wax mold according to the confirmed design plan. The wax mold is the basis for the subsequent casting process.

- The wax model can be made by hand carving or 3D printing technology.

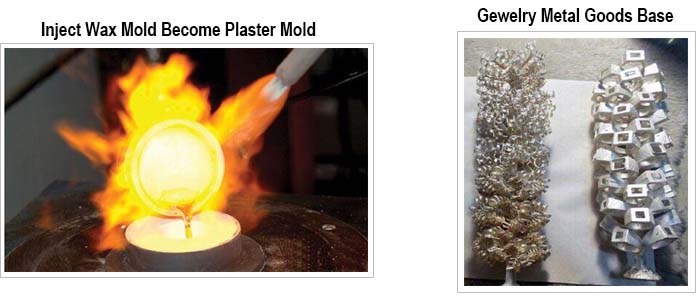

2. Lost wax casting:

- Wrap the wax model in a refractory material to form a mold.

- Heat the wax to melt and flow out, then pour the molten silver into the mold, and cool it to form the prototype of the silver jewelry.

3. Polishing and finishing:

- Polish and finish the cast silver jewelry to remove excess burrs and uneven parts.

- Polishing to make the surface of the silver jewelry smooth and bright.

4. Assembly and inlay:

- If there are multiple parts in the design or gemstones need to be inlaid, assemble and inlay them.

- Ensure that each part is firmly connected and the inlaid gemstones are stable and beautiful.

III. Quality inspection stage

1. Quality inspection:

- Carry out strict quality inspection on the finished product to ensure that each piece of silver jewelry meets the design requirements and quality standards.

- The inspection content includes size, weight, surface finish, gemstone inlay firmness, etc.

2. Cleaning and packaging:

- Clean the silver jewelry to remove impurities and stains left over from the production process.

- Use professional packaging materials for packaging to protect the silver jewelry from damage during transportation and storage.

IV. Delivery stage

1. Finished product display and confirmation:

- Display the finished silver jewelry to the customer for final confirmation.

- Ensure that the customer is satisfied with the finished product, and make timely adjustments and modifications if there are any problems.

2. Delivery and after-sales service:

- Deliver the silver jewelry to the customer and provide corresponding after-sales service.

- Including maintenance instructions, repair services, etc., to ensure that customers can enjoy the beauty and value of silver jewelry for a long time.

Through the above detailed steps, the custom processing of silver jewelry requires careful preparation and strict control from the design sketch to the final product to ensure that each piece of silver jewelry is a unique work of art that meets the expectations and needs of customers.