JINGYING: The Reliable Powerhouse in Custom Jewelry Manufacturing

In the dynamic and ever-evolving world of jewelry, where trends shift with the seasons and consumer demands grow increasingly sophisticated, the backbone of success lies not just in design, but in manufacturing excellence. For brands, designers, and entrepreneurs seeking a partner to transform visionary concepts into tangible, high-quality artifacts, reliability is the most coveted currency. Enter JINGYING, a name that has come to epitomize reliability, precision, and mastery in custom jewelry manufacturing. Specializing in the nuanced crafts of sterling silver, gold plating, gold vermeil, and gold filled pieces, JINGYING stands as a formidable ally for those who require nothing less than exceptional quality and steadfast partnership.

I. The Pillars of Reliability: What Sets JINGYING Apart

Reliability in manufacturing is a multidimensional construct. It is not merely about delivering on time, but about consistent quality, transparent communication, ethical practices, and technical expertise. JINGYING has built its reputation on these very pillars.

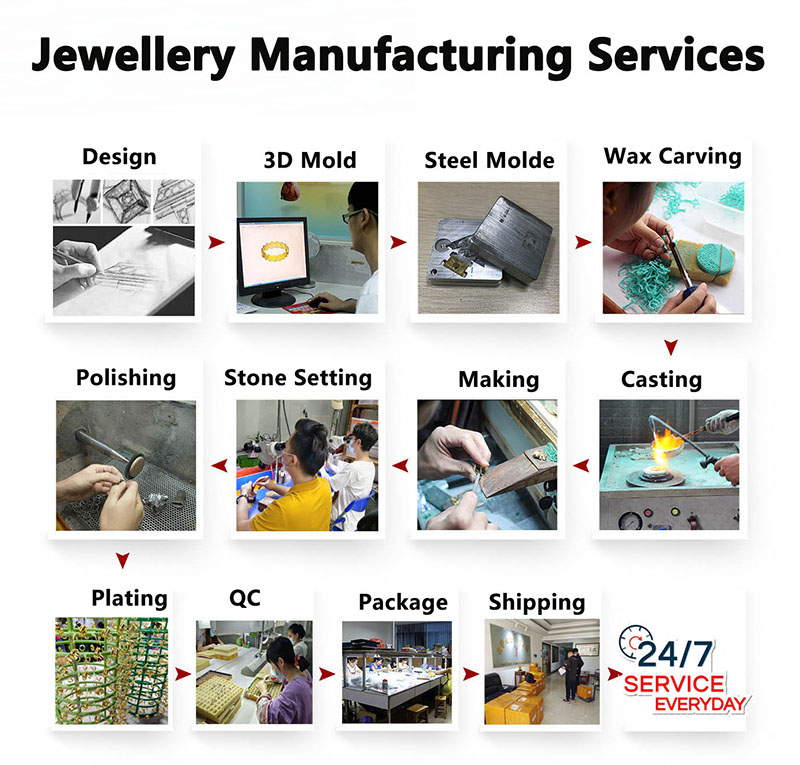

- Technical Proficiency and State-of-the-Art Facilities: At the heart of JINGYING’s operations is a commitment to technological advancement paired with artisanal skill. Housing advanced CAD/CAM systems, precision casting equipment (like vacuum and centrifugal casting), automated polishing stations, and rigorous quality control laboratories, JINGYING ensures every piece, from the simplest pendant to the most intricate statement ring, is engineered to perfection. Their technicians and master craftsmen possess deep metallurgical knowledge, understanding the specific behaviors and requirements of each material they handle.

- Uncompromising Quality Control (QC): Reliability is meaningless without consistency. JINGYING implements a multi-stage QC protocol that scrutinizes every piece at each phase of production—from raw material inspection and 3D printed model verification to post-casting integrity, plating thickness measurement, and final aesthetic appraisal. This systemic approach minimizes errors and guarantees that every shipment meets the stringent standards promised.

- Transparent and Collaborative Communication: JINGYING operates on a partnership model. They assign dedicated project managers who serve as a single point of contact, guiding clients through the entire process—from initial design feedback and prototyping to production scheduling and logistics. This transparency in timelines, costs, and potential challenges builds trust and allows clients to plan with confidence.

- Ethical and Sustainable Practices: In the modern marketplace, reliability extends to ethical sourcing and environmental responsibility. JINGYING is committed to sourcing recycled sterling silver and gold where possible, adhering to responsible waste management protocols, and ensuring safe, fair working conditions. This ethical backbone assures clients that their brand values are upheld throughout the supply chain.

- Scalability and Flexibility: Whether a client needs a limited edition run of 50 pieces or a large-scale production of 50,000, JINGYING’s infrastructure is designed to scale efficiently. Their reliability shines in their ability to maintain quality and timeliness regardless of order volume, adapting to the evolving needs of startups and established brands alike.

II. Mastering the Materials: A Deep Dive into JINGYING’s Core Competencies

JINGYING’s expertise is most vividly demonstrated in its masterful handling of specific materials and techniques, offering clients a spectrum of options to match their design vision, quality expectations, and price points.

1. The Foundation: 925 Sterling Silver

Sterling silver is the cornerstone of modern affordable luxury jewelry. JINGYING’s work with 925 Sterling Silver (92.5% pure silver, 7.5% alloy, typically copper for strength) is exemplary. They understand that successful silver pieces require precision in casting to avoid porosity, expertise in finishing to achieve a flawless mirror polish or intentional matte texture, and careful handling to prevent scratches and tarnish during production. For custom designs, they excel at:

- Complex Sculptural Pieces: Leveraging high-resolution 3D printing and precise casting to capture fine details.

- Mechanical Components: Producing hinged pieces, clasps, and interlocking elements with smooth functionality.

- Surface Texture Application: Creating unique effects through hammering, engraving, sandblasting, or etching.

The reliability here lies in delivering sterling silver pieces that are not only beautiful but also durable, well-finished, and ready for wear or further enhancement through plating.

2. The Luxurious Standard: Gold Plating and the Gold Vermeil Distinction

Gold plating is a ubiquitous technique, but its quality varies drastically. JINGYING educates its clients and rigorously applies the critical differences, ensuring informed choices.

- Standard Gold Plating: They offer quality gold plating over various base metals (like brass or sterling silver), with clear specifications on gold karat (14k, 18k) and thickness. While an economical choice, they are transparent about its limitations regarding durability.

- The JINGYING Standard: Gold Vermeil (Pronounced ver-May): This is where JINGYING truly distinguishes itself. They adhere to and champion the strict, industry-respected standards for vermeil:

- Base: 925 Sterling Silver only.

- Plating: 18k Gold or higher.

- Thickness: A minimum of 2.5 microns.

This trifecta is non-negotiable. The sterling silver base provides value, hypoallergenic properties, and a superior foundation compared to brass or nickel silver. The 18k gold plating offers a rich, authentic gold color with less susceptibility to tarnishing than lower karats. Most critically, the minimum 2.5-micron thickness is the key to longevity. Unlike typical plating measured in fractions of a micron (often 0.5 microns or less), this substantial layer can withstand years of careful wear before showing signs of wear on high-contact areas.

JINGYING’s reliability in vermeil production is proven through advanced electrolytic plating processes that ensure an even, consistent coating. They use state-of-the-art X-ray fluorescence (XRF) gauges to verify thickness at multiple points on every piece, providing clients with the assurance that their “vermeil” label is honest and defensible. For clients seeking affordable luxury with exceptional durability and a clear conscience about material claims, JINGYING’s gold vermeil is the benchmark.

3. The Durable Heirloom: Gold Filled

For clients whose designs demand exceptional durability for daily wear—such as signet rings, bracelets, or classic hoops—JINGYING expertly executes Gold Filled manufacturing. They clarify this often-misunderstood term by adhering to its legal and material definition:

- Construction: A solid layer of gold (typically 10k, 12k, or 14k) is mechanically bonded through heat and pressure to a core of brass (sometimes sterling silver, but brass is standard for gold filled).

- Gold Content: The gold layer must constitute at least 1/20th (5%) of the total weight of the item.

The process requires significant expertise. JINGYING’s artisans skillfully handle the sheets of gold-filled material, ensuring the bonding remains intact during the stamping, forming, and soldering processes. The result is a product that possesses nearly all the aesthetic and anti-tarnish qualities of solid gold but at a fraction of the cost. It is vastly more durable than any plating, capable of lasting a lifetime without wearing through. JINGYING’s reliability in this domain ensures clients receive jewelry that lives up to the “heirloom-quality” promise, with the material integrity to match.

III. The Custom Design Journey: From Sketch to Reality

JINGYING’s reliability is perhaps most palpably felt by designers during the custom creation process. They have systemized creativity.

- Consultation and Design Feasibility: The journey begins with a collaborative review of client ideas—whether sketches, inspirations, or CAD files. JINGYING’s engineers provide practical feedback on design for manufacturability (DFM), suggesting modifications to enhance durability, reduce costs, or improve comfort without compromising artistic intent.

- 3D CAD Modeling and Prototyping: Their skilled CAD designers create precise, watertight 3D models. Clients then have the option to review a 3D render or receive a physical prototype (often in wax or resin via 3D printing) to assess form, fit, and proportion before committing to metal.

- Material Selection and Sampling: Guided by JINGYING, clients select the perfect material strategy—be it solid sterling silver, vermeil for certain components, or gold-filled for others. Custom finish samples (e.g., a specific brush texture or a unique gold plating hue) are created for approval.

- Production with Continuous Communication: Once the prototype and samples are approved, production begins. The dedicated project manager provides updates, and pre-shipment photos or videos are often shared for final validation, eliminating unpleasant surprises upon delivery.

- Final QC, Packaging, and Logistics: Every batch undergoes final QC against the approved sample. JINGYING also offers customized packaging solutions, from simple poly bags to branded boxes, and manages reliable international logistics, providing tracking and handling customs documentation.

IV. Serving a Global Clientele: Tailored Partnerships

JINGYING’s reliable manufacturing serves a diverse ecosystem:

- Startups and Entrepreneurs: They provide the essential hand-holding, minimum order quantity (MOQ) flexibility, and education needed to launch a successful first collection.

- Established Jewelry Brands: For these clients, JINGYING acts as a seamless extension of their own production team, offering capacity, specialized technique execution, and consistent quality that aligns with an existing brand reputation.

- E-commerce and DTC Brands: Speed-to-market and photographic consistency are key. JINGYING’s efficient timelines and ability to produce perfectly finished pieces that look impeccable online are critical assets.

- Designers and Artists: They offer the technical translation services to realize highly conceptual, artistic pieces that may challenge conventional manufacturing limits.

V. Conclusion: The Bedrock of Brand Success

In an industry where a single production flaw can damage a brand’s reputation and a delayed shipment can miss a crucial market window, the choice of manufacturer is a strategic business decision of paramount importance. JINGYING has positioned itself not merely as a factory, but as a Reliable Manufacturing Partner.

Their deep, transparent expertise in 925 Sterling Silver, their unwavering commitment to the high standards of Gold Vermeil (2.5 microns of 18k gold over sterling silver), and their proficient mastery of durable Gold Filled (5% gold by weight) construction provide clients with a trustworthy palette of material options. Coupled with a transparent, communicative process, rigorous QC, and ethical operations, JINGYING offers something invaluable: certainty.

For any brand aiming to build a legacy of quality, to delight customers with pieces that endure, and to scale with confidence, partnering with a manufacturer like JINGYING is not just an option—it is the foundational step toward sustainable success. In the world of custom jewelry, where dreams are forged in metal, reliability is the most precious alloy, and JINGYING delivers it in abundance.