In the intricate and fiercely competitive world of jewellery manufacturing, the quest for a reliable partner is not merely a business decision; it is the foundational pillar upon which brands build their reputation, creativity, and commercial success. For designers, brands, and entrepreneurs seeking to transform visionary designs into tangible, exquisite pieces, the manufacturing phase presents a labyrinth of potential challenges—quality inconsistencies, communication breakdowns, logistical nightmares, and ethical ambiguities. It is within this complex landscape that a partner like JINGYING emerges not just as a supplier, but as a critical ally. Specializing in the production of custom 925 sterling silver jewellery components, JINGYING has established itself as a paragon of reliability, a manufacturer whose core operational ethos is built on precision, transparency, collaboration, and unwavering consistency. This article delves into the multifaceted nature of JINGYING’s reliability, exploring how its mastery of materials, technological prowess, stringent quality protocols, and client-centric philosophy collectively define what it means to be a truly dependable manufacturing partner in the silver jewellery industry.

I. The Bedrock of Reliability: Mastery of Material and Metallurgical Excellence

Reliability in jewellery manufacturing begins, quite literally, at the molecular level. For a component manufacturer, there is no greater testament to dependability than an uncompromising command over the primary material. JINGYING’s specialization in 925 sterling silver is the first and most crucial pillar of its trustworthiness.

1.1 The Unyielding Commitment to 925 Standard:

Sterling silver is an alloy, traditionally composed of 92.5% pure silver and 7.5% other metals, usually copper. This specific ratio is not arbitrary; it is the optimal balance that retains the luminous beauty and workability of pure silver while bestowing the necessary hardness and durability for jewellery that must withstand daily wear. JINGYING’s reliability is instantly demonstrated in its scrupulous adherence to this standard. They source only certified, high-purity silver and alloy materials from reputable suppliers, often providing mill certificates or assay guarantees upon request. This ensures that every batch of material entering their production line is genuine 925 sterling silver, eliminating the risk of sub-standard alloys that can lead to discoloration (excessive tarnishing due to high copper content), brittleness, or allergic reactions. For clients, this means the foundational material of their components is consistently excellent, forming a predictable and high-quality base for all subsequent manufacturing steps.

1.2 Advanced Alloy Management and Anti-Tarnish Considerations:

Beyond basic compliance, JINGYING’s expertise extends to sophisticated alloy management. They understand that the 7.5% “other metals” can be engineered. By utilizing high-purity copper and sometimes incorporating minute traces of elements like germanium or platinum, they can enhance the tarnish-resistance of their sterling silver without compromising its hallmark or legal standard. This proactive approach to material science prevents a common point of failure in silver jewellery and adds immense value for clients whose brands are built on longevity and customer satisfaction. Furthermore, their in-house metallurgical knowledge allows them to advise clients on the best alloy specifications for specific component functions—for instance, a slightly harder temper for a delicate clasp mechanism versus a more malleable one for intricate hand-chased details.

1.3 Material Traceability and Ethical Sourcing:

In the modern marketplace, reliability also encompasses ethical and sustainable practices. JINGYING strengthens its partner status by often providing traceability for its silver sources, ensuring they originate from conflict-free and responsibly managed mines and refiners. This commitment to ethical sourcing protects client brands from association with dubious supply chains and aligns with the growing consumer demand for transparency. It demonstrates that JINGYING’s reliability is holistic, covering not only the physical quality of the material but also the integrity of its provenance.

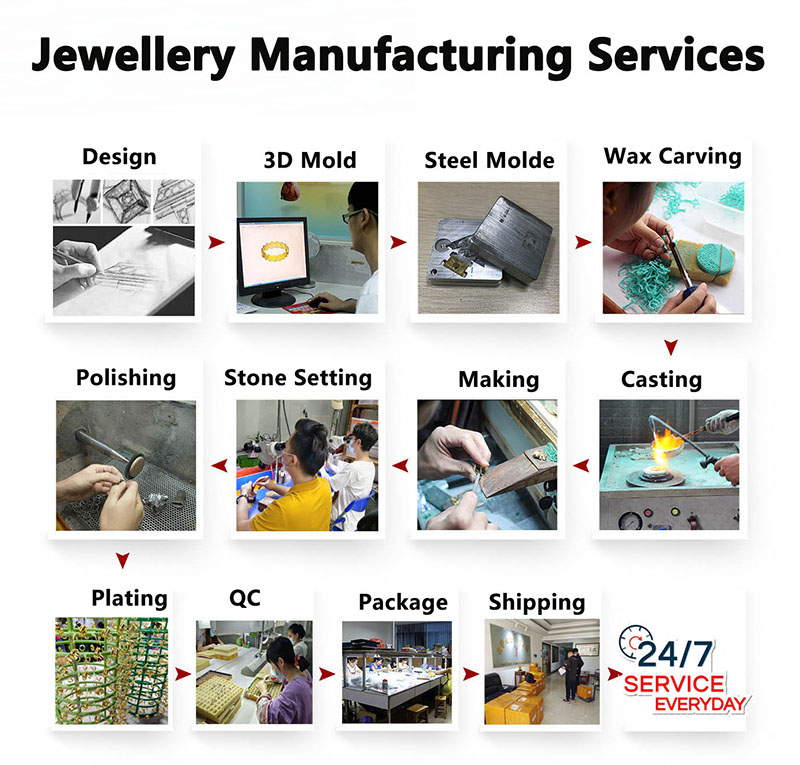

II. The Architecture of Precision: Technological Prowess and Manufacturing Capabilities

A reliable partner must possess the technical arsenal to execute designs flawlessly, from the simplest band to the most architecturally complex component. JINGYING’s investment in state-of-the-art technology and diverse manufacturing techniques creates a robust infrastructure for precision.

2.1 Digital Design Integration and CAD/CAM Mastery:

The journey of a custom component begins with a design. JINGYING bridges the gap between digital imagination and physical reality through advanced Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) capabilities. Their engineers are adept at working with client-provided CAD files (from software like Rhino 3D, Matrix, or ZBrush) and can also transform hand-drawn sketches or even verbal concepts into precise, manufacturable 3D models. This digital partnership is a cornerstone of reliability. They conduct thorough DFM (Design for Manufacturability) analyses, identifying potential issues such as structural weak points, impractical tolerances, or casting difficulties before a single gram of silver is used. This proactive problem-solving prevents costly errors and production delays, ensuring the design is optimized for both beauty and manufacturability.

2.2 Versatile Formation Techniques:

JINGYING’s reliability is fortified by its versatility across multiple production methods, allowing it to recommend and execute the ideal technique for each component:

- Investment Casting (Lost-Wax Casting): The industry standard for detailed, complex, and sculptural components. JINGYING’s precision in creating wax models (via 3D printing or traditional carving) and controlling the casting process in high-temperature vacuum or centrifugal machines results in components that capture extraordinary detail, from textured surfaces to intricate filigree, with minimal metal waste and excellent reproducibility.

- Stamping and Die-Striking: For simpler, flatter, or high-volume components like charms, links, or findings, stamping offers exceptional efficiency and consistency. JINGYING’s capability to design and fabricate precision-hardened steel dies ensures that every stamped component is identical, with sharp, clean edges and defined features. This method is a testament to reliability in volume production, where uniformity across tens of thousands of pieces is non-negotiable.

- CNC (Computer Numerical Control) Milling: For components requiring absolute geometric precision, such as hinges, interlocking mechanisms, or pieces with exacting engineering tolerances, CNC milling is indispensable. JINGYING’s multi-axis CNC machines carve components directly from solid blocks of sterling silver, achieving accuracy measured in microns. This capability is crucial for clients producing modular jewellery or tech-focused wearables where components must fit together with perfect, repeatable alignment.

- Hand Fabrication and Assembly: For small batches, bespoke pieces, or final assembly, JINGYING complements its technological might with skilled artisan craftsmanship. Soldering, polishing, setting, and assembly by experienced technicians ensure that even the most technologically produced components are finished with a human touch, achieving a level of refinement machines alone cannot provide.

2.3 Seamless Production Scalability:

A truly reliable partner must scale alongside its clients. JINGYING’s manufacturing ecosystem is designed for seamless scalability. Whether a client needs a prototype run of 50 pieces, a mid-range order of 5,000, or a large-scale production of 500,000 components, JINGYING can adjust its workflow efficiently. Their production planning and shop floor management are engineered to maintain consistent quality and lead times regardless of order volume, eliminating the common industry pain point where scaling up leads to a breakdown in quality control.

III. The Uncompromising Gatekeeper: Stringent Quality Assurance and Control

Technology and materials mean little without a rigorous system to govern them. JINGYING’s most visible expression of reliability is its omnipresent, multi-stage Quality Assurance (QA) and Quality Control (QC) protocol. This is not a final inspection but a philosophy embedded in every step of the process.

3.1 In-Process Quality Checks:

Quality is monitored in real-time. During casting, samples are checked for porosity and completeness of fill. During stamping or milling, first-article inspections verify that dimensions match the CAD model exactly. Surface finish, solder joint integrity, and mechanical function (e.g., of spring rings or clasps) are assessed at dedicated stations before components proceed to the next stage. This continuous monitoring prevents a single error from cascading through the entire production run, saving time and material.

3.2 Final Inspection and Metrology:

Before shipment, every batch of components undergoes a final, exhaustive inspection. This involves both human expertise and advanced metrology tools. Skilled QC inspectors examine samples under magnification for surface defects, finishing consistency, and overall aesthetics. Meanwhile, tools like coordinate measuring machines (CMM), laser scanners, and optical comparators are used to verify critical dimensions against the technical drawings, ensuring tolerances are held within specified limits (often as tight as ±0.05mm). This combination of artisanal scrutiny and digital verification provides a dual-layer assurance of quality.

3.3 Finishing and Surface Treatment Excellence:

The perceived quality of a jewellery component is profoundly affected by its finish. JINGYING offers a comprehensive range of in-house finishing services, each performed to a consistent standard:

- Polishing: From a high-gloss mirror polish to a soft satin or brushed finish, polishing techniques are executed with precision to achieve uniform luster across all components in an order.

- Plating: For components requiring gold (yellow, rose, white) or rhodium plating, JINGYING employs advanced electroplating processes with strict thickness control (measured in microns). They ensure proper preparation and plating adhesion to prevent peeling or wear, a common failure point in plated jewellery.

- Oxidation and Patination: For antique or highlighted effects, controlled oxidation is applied skillfully and sealed to stabilize the finish.

- Quality in Packaging: Reliability extends to packaging. Components are individually bagged in anti-tarnish pouches, organized clearly by style and order number, and packed securely to prevent damage in transit. This attention to the final detail ensures products arrive in pristine, ready-to-use condition.

IV. The Human Factor: Communication, Collaboration, and Client-Centric Service

Beyond machines and metals, reliability is ultimately a human endeavor. JINGYING distinguishes itself through a service model built on transparent communication, collaborative problem-solving, and educational partnership.

4.1 Transparent and Proactive Communication:

From the initial quote to the delivery notification, JINGYING maintains clear, timely, and professional communication. They assign dedicated project managers who serve as a single point of contact, providing updates, answering technical questions, and managing timelines. This eliminates the frustration of navigating a faceless corporation. Importantly, they communicate proactively—if a potential delay is spotted in the supply chain or a design issue is identified, they inform the client immediately with proposed solutions, not as a last-minute surprise. This transparency builds immense trust.

4.2 Collaborative Problem-Solving and Design Support:

JINGYING positions itself as an extension of its clients’ R&D teams. Their engineers and consultants do not simply take orders; they engage in dialogue. They might suggest a slight design modification to enhance durability, recommend a more cost-effective manufacturing method without compromising design intent, or propose alternative finishes to achieve a desired aesthetic. This collaborative spirit transforms the client-manufacturer relationship from a transactional one into a creative and strategic partnership, where JINGYING’s deep manufacturing intelligence actively contributes to the client’s success.

4.3 Prototyping and Sampling Integrity:

The prototyping phase is where trust is forged. JINGYING treats prototypes with the same seriousness as full production runs. They provide accurate, functional prototypes in sterling silver (not just in cheaper metals), allowing clients to test fit, form, function, and market appeal. Any adjustments are made iteratively until the client is fully satisfied. This commitment to “getting it right” before mass production is a critical risk-mitigation service for clients, protecting them from the catastrophic cost of launching a flawed product.

4.4 Educational Guidance and Market Intelligence:

A reliable partner educates. JINGYING often guides newer clients through industry standards, explains cost drivers, advises on seasonal production planning to optimize lead times, and shares insights on finishing trends or new technological advancements. This knowledge transfer empowers clients to make better business decisions and deepens the symbiotic relationship.

V. The Proof is in the Partnership: Outcomes and Industry Reputation

The culmination of JINGYING’s approach to reliability is evidenced in tangible outcomes for its clients and its standing within the industry.

5.1 Client Outcomes: Reduced Risk and Enhanced Brand Equity:

For clients, partnering with JINGYING translates directly into reduced business risk and strengthened brand equity. Consistent quality means fewer customer returns and complaints. On-time delivery facilitates smooth inventory management and retail planning. Ethical compliance safeguards brand reputation. Ultimately, the reliability of their manufacturing partner allows designers and brands to focus their energy on what they do best: designing, marketing, and building their customer relationships, secure in the knowledge that their supply chain backbone is solid.

5.2 Industry Recognition and Long-Term Relationships:

In an industry where word-of-mouth is paramount, JINGYING’s reputation for reliability precedes it. They are often the recommended manufacturer for custom components by tool suppliers, design schools, and industry consultants. Their most powerful testament is their roster of long-term clients—brands that have grown with them over years or decades. These enduring relationships, built on consistently met expectations and successfully navigated challenges, are the ultimate benchmark of a reliable manufacturing partner.

Conclusion

In the demanding realm of custom 925 sterling silver jewellery component manufacturing, reliability is a comprehensive attribute, woven from threads of material integrity, technical excellence, rigorous quality control, and human-centric collaboration. JINGYING embodies this synthesis. It is more than a factory; it is a partner that provides the stability and expertise necessary for creative businesses to thrive. By mastering the science of its material, leveraging technology for precision, enforcing uncompromising quality standards, and fostering transparent partnerships, JINGYING does not merely produce components—it manufactures confidence. For any brand seeking to transform its silver jewellery visions into a reality that is beautiful, consistent, and market-ready, aligning with a partner of JINGYING’s caliber is not just a smart choice; it is a strategic imperative for sustainable success. In the alchemy of turning silver into value, JINGYING proves itself to be the reliable catalyst for excellence.