JINGYING: The Art of Enduring Adornment – Where Quality, Durability, and Bespoke Craftsmanship Converge

Introduction

In the dynamic and often ephemeral world of fashion jewelry, where trends flicker and fade with the seasons, a distinct segment demands more than mere transitory beauty. It seeks substance, longevity, and a tangible sense of value. This is the realm of enduring adornment, where pieces are not simply worn but invested in, becoming part of a personal narrative over years, not just months. Standing firmly at the intersection of superior craftsmanship, unwavering material integrity, and collaborative client vision is JINGYING, a premier manufacturer redefining expectations for quality jewelry and bespoke manufacturing services.

JINGYING operates on a foundational principle: that jewelry, whether a fashion statement or a personal treasure, should be defined by its resilience and enduring appeal. As both a creator of its own high-caliber collections and a masterful provider of Private Label and OEM (Original Equipment Manufacturing) services, JINGYING bridges the gap between aspirational design and tangible, reliable production. The company specializes in crafting pieces from meticulously plated base metals—copper gold-plated and sterling silver (925) gold-plated—while also possessing the expertise and infrastructure to venture into solid gold, thereby offering a spectrum of luxury. At its core, however, is a relentless, almost obsessive focus on three pillars: exceptional quality, inherent durability, and long-lasting plating. This trinity forms the DNA of every piece that leaves its workshops, making JINGYING not just a manufacturer, but a guarantor of longevity in an industry prone to compromise.

This essay delves into the essence of JINGYING’s philosophy, exploring its material science, its manufacturing ethos, the dual engine of its business model (in-house lines and client-driven services), and its pivotal role in empowering brands in a competitive marketplace. It posits that in an age of conscious consumption, JINGYING’s commitment to durability is not just a technical specification but a strategic and ethical stance, offering sustainability through longevity.

Chapter 1: The Philosophy of Durability – Beyond the Surface

For JINGYING, durability is not an afterthought or a marketing buzzword; it is the primary design constraint and the ultimate goal. This philosophy stems from a profound understanding of jewelry’s relationship with the human body and daily life.

The Adversaries of Jewelry: Everyday jewelry faces a relentless battery of challenges. Skin acidity (pH levels), perspiration, cosmetics, perfumes, chlorinated or saltwater, and simple abrasion from contact with clothing and surfaces—all conspire to degrade materials, tarnish surfaces, and cause plating to wear thin, revealing the base metal beneath in an unsightly and often allergenic manner. Cheap, mass-produced jewelry succumbs quickly to these forces, leading to discoloration, breakage, and a disappointingly short lifecycle. This “fast jewelry” phenomenon contributes to a cycle of waste and dissatisfaction.

JINGYING’s Proactive Defense: JINGYING’s approach is one of proactive engineering. Durability is built in at every stage:

- Structural Integrity: Designs are evaluated not only for aesthetics but for physical soundness. Stress points in clasps, rings, and chains are reinforced. Findings (the functional components like clasps, jump rings, and earring posts) are selected or custom-made for robustness, ensuring that a piece can withstand the tension and manipulation of daily wear.

- Material Preparation: The journey to a long-lasting finish begins long before the plating tank. For plated pieces, the base metal—be it copper or sterling silver—is prepared to surgical standards. This involves meticulous polishing to a flawless surface, followed by intensive cleaning and degreasing to remove any microscopic contaminants. Any imperfection left on the base metal will be amplified under the plating layer and become a failure point.

- The Plating as Armor: The plating process is where JINGYING’s expertise truly shines. The company employs advanced electroplating techniques, moving far beyond simple dip-plating. Key to their success is the control of plating thickness, measured in microns. While many manufacturers apply a sub-micron flash of gold for immediate color, JINGYING ensures a substantially thicker, even layer of high-karat gold (often 14K, 18K, or 22K depending on the desired hue and application). This thickness is the direct determinant of how long the gold finish will last before wearing through. Furthermore, the electrochemical bond between the base metal and the gold layer is optimized for adhesion, preventing peeling or blistering.

The Outcome – Emotional Durability: The practical result is jewelry that resists tarnish, maintains its color, and withstands daily life. The emotional result is trust. A customer who buys a JINGYING piece, or a brand that partners with them, gains confidence. The piece becomes a reliable companion, its beauty not diminishing with the first touch of rain or perfume. This builds brand loyalty and turns customers into advocates. Durability, therefore, translates directly into brand equity and customer satisfaction.

Chapter 2: The Materials Palette – A Foundation of Quality

JINGYING’s commitment begins with its curated selection of materials, each chosen for its specific properties and role in the final product’s life.

1. Copper Gold-Plated:

- The Base – Copper: Copper is an excellent choice for base metal due to its malleability, allowing for intricate and detailed designs, and its excellent conductivity, which is crucial for even electroplating. It is also relatively hardy. JINGYING uses high-grade, alloyed copper where necessary to enhance strength for specific components.

- The Transformation – Gold Plating: The copper is plated with a substantial layer of genuine gold. The thickness, purity, and plating technique (such as pulse plating for better density and distribution) are controlled to create a finish that is rich, warm, and durable. For added protection, especially on pieces likely to face more wear (like rings), JINGYING often applies a clear, hard protective coating (like a rhodium-based or specialty polymer sealant) over the gold. This invisible barrier shields against scratches and chemicals, extending the pristine life of the gold layer immensely.

2. Sterling Silver (925) Gold-Plated:

- The Premium Base – Sterling Silver (925): This is where JINGYING offers a significant upgrade. Sterling silver, an alloy of 92.5% pure silver and 7.5% other metals (usually copper for strength), is a premium base material in its own right. It is naturally hypoallergenic, has a brilliant white luster, and intrinsic value. Using sterling silver as a base elevates the entire piece.

- The Luxurious Fusion – Vermeil: When sterling silver is plated with a thick layer of gold (typically 2.5 microns or more), the result qualifies as vermeil—a legally defined standard for luxury gold-plated jewelry. JINGYING’s sterling silver gold-plated pieces often meet or exceed vermeil standards. This combination offers the best of both worlds: the weight, feel, and tarnish-resistance (the gold layer protects the silver underneath) of a precious metal, with the beauty of gold, at a cost accessible to a wider audience than solid gold. It represents a core segment of JINGYING’s quality proposition.

3. Solid Gold Options:

- The Apex of Permanence: While plating technology is advanced, solid gold represents the ultimate in durability and legacy. Solid gold pieces (be they 10K, 14K, 18K, or 22K) are inherently resistant to tarnish and corrosion. The color is throughout the piece, so it never wears off. JINGYING’s capability in this area signifies its top-tier craftsmanship. Working with solid gold requires different tooling, expertise in alloying for color and strength, and a mastery of fabrication techniques for precious metals. By offering this potential, JINGYING positions itself as a full-spectrum partner, capable of guiding a client from a plated concept to a solid gold heirloom collection.

Chapter 3: The Manufacturing Ethos – Precision, Process, and Control

JINGYING’s philosophy is actualized on its factory floor through a culture of precision and rigorous process control.

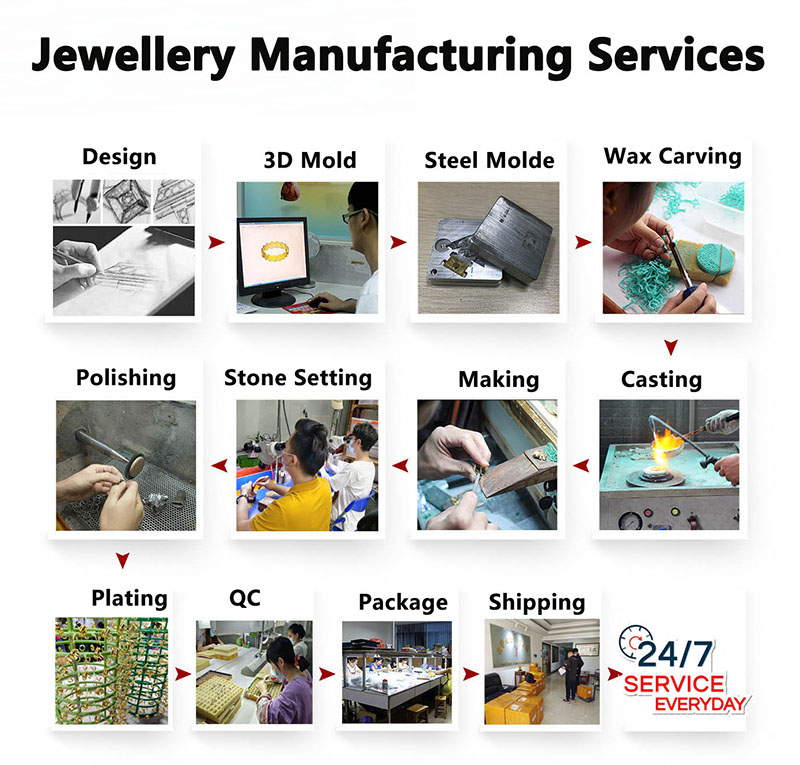

A. The Production Workflow:

- Design & Technical Analysis: Whether for an in-house line or a client’s OEM project, each design undergoes a feasibility review. Engineers assess mold-making, casting integrity, plating coverage, and assembly complexity.

- Prototyping & Sampling: High-quality prototypes (often in brass or silver) are created for approval. This stage is crucial for verifying aesthetics, fit, and function before full-scale production.

- Model & Mold Making: Master models are crafted with precision. For casting, high-grade steel or rubber molds are created to ensure crisp, consistent reproductions of the design.

- Casting & Formation: Metals are cast using methods like lost-wax casting for detail or are formed through stamping and machining. Deburring and initial polishing follow to remove any rough edges.

- The Crucible of Quality: Pre-Plating Finishing: This is arguably the most critical phase for durability. Pieces undergo multiple stages of polishing—from coarse to mirror-finish—using specialized wheels and compounds. They are then ultrasonically cleaned in multi-stage baths to remove all polishing residues and oils. A perfectly clean surface is non-negotiable.

- Electroplating: In controlled, temperature-regulated baths, the plating occurs. Anodes of the plating metal (gold, etc.) dissolve, and the jewelry, acting as the cathode, is evenly coated. Current density, bath chemistry, and time are meticulously monitored to achieve the specified thickness and color.

- Post-Plating Protection & Assembly: After plating, pieces may receive a protective coating. They are then assembled by skilled technicians—setting stones (if any), attaching secure clasps, and ensuring every link and joint is sound.

- Final Inspection & Quality Assurance (QA): Every single piece is inspected for plating uniformity, color match, surface defects, and functional integrity. Statistical quality control methods are employed to maintain consistent standards across thousands of units.

B. Investment in Technology: JINGYING’s commitment is backed by investment in modern plating rectifiers, automated polishing lines, advanced filtration systems for plating baths, and sophisticated QA equipment like thickness testers and spectrophotometers for color consistency. This blend of skilled handwork and technological oversight ensures scalable quality.

Chapter 4: The Dual Engine: In-House Excellence and Bespoke Partnership

JINGYING’s business model is strategically bifurcated, serving two interconnected markets.

A. The Manufacturer’s Collection – A Showcase of Capability:

JINGYING’s own branded or non-branded collections serve as a living catalog of its capabilities. These lines demonstrate the company’s design sensibility, trend awareness, and, most importantly, the tangible quality it champions. Retailers or distributors buying these ready-made pieces get access to jewelry that already embodies the JINGYING standard of durability and finish, with the benefits of quicker lead times and lower minimum order quantities (MOQs) than fully custom projects. These collections act as both a revenue stream and the most convincing sales pitch for its OEM services.

B. Private Label & OEM Services – Empowering Brands:

This is where JINGYING transitions from a supplier to a strategic partner. In today’s market, brands—from ambitious startups to established fashion houses—seek unique identity and control over their product. JINGYING provides the infrastructure to realize this vision.

- Private Label: A brand selects from JINGYING’s existing catalog of designs, and the pieces are produced and delivered branded with the client’s logo and packaging. It’s a fast-track to a cohesive collection backed by reliable quality.

- OEM / Custom Manufacturing: This is full-service co-creation. A client brings their own designs (from sketches to 3D files). JINGYING’s team provides material consultation, technical design optimization, prototyping, sampling, mass production, quality control, and customized packaging. This service is invaluable for brands that want exclusive designs without the colossal capital expenditure of building their own factories and supply chains.

The Partnership Advantage: JINGYING’s role as an OEM partner goes beyond fabrication. It is a consultant on material selection (advising when vermeil is preferable or when to consider solid gold), a guide on cost-effective design tweaks that maintain integrity, and a guarantor of supply chain reliability. For a brand, this partnership mitigates risk and accelerates time-to-market with a product they can stand behind with confidence.

Chapter 5: The Market Impact – Filling a Critical Niche

JINGYING occupies a crucial and often underserved niche in the global jewelry ecosystem.

1. Bridging the “Quality Gap”: The market is polarized between low-cost, disposable fashion jewelry and high-end fine jewelry. JINGYING operates in the vital middle—the ”accessible luxury” or ”high-end fashion jewelry” segment. It offers the aesthetic appeal and perceived value of luxury with the durability that is often missing from standard fashion jewelry, yet at a price point far below solid gold. This meets the growing consumer demand for “investment” in better fast fashion—pieces that cost more upfront but deliver vastly more wear and enjoyment.

2. Enabling the Rise of Direct-to-Consumer (DTC) and Niche Brands: The explosion of DTC jewelry brands, fueled by social media and e-commerce, relies heavily on manufacturers like JINGYING. These brands thrive on unique stories and quality perceptions. JINGYING provides them with the product credibility needed to build their reputation. A positive customer review noting “the plating hasn’t faded even after months of daily wear” is marketing gold for these brands, and it originates from JINGYING’s production standards.

3. Contributing to Sustainable Consumption: While not “green” in the traditional recycled-material sense, durability is a powerful form of sustainability. A longer product lifecycle means fewer pieces discarded, fewer resources consumed in replacement, and less waste. By creating jewelry that lasts for years instead of seasons, JINGYING inherently promotes a more sustainable consumption model. Educating both its brand partners and end-consumers about proper care (e.g., storing pieces properly, avoiding chemicals) further extends this lifecycle.

Conclusion: The Lasting Legacy of JINGYING

In the final analysis, JINGYING represents more than a manufacturing facility in the jewelry supply chain. It embodies a principle that is both timeless and increasingly urgent: that quality and durability are not luxuries, but essential components of value and responsible creation.

Through its mastery of materials—from robust copper and premium sterling silver bases to the potential of solid gold—and its surgical precision in plating and finishing, JINGYING builds more than jewelry; it builds trust. This trust flows through two primary channels: directly to the wearer who experiences the resilience of the piece, and to the brand partner who stakes its reputation on the product’s performance.

As both a creator of its own exemplary collections and a behind-the-scenes architect for countless brands worldwide, JINGYING plays a dual role as a standard-bearer and an enabler. In a world saturated with transient goods, JINGYING’s focus on creating pieces with lasting beauty and integrity is a competitive advantage and a quiet statement of ethos. It proves that in the realm of adornment, true style is not about fleeting trends, but about the enduring confidence that comes from something exceptionally well-made. For the discerning brand and the conscious consumer, JINGYING is not merely a source of jewelry; it is the foundation for a lasting story of style and substance.