JINGYING: Custom Gold-Plated Pendant Manufacturing from Your CAD Design

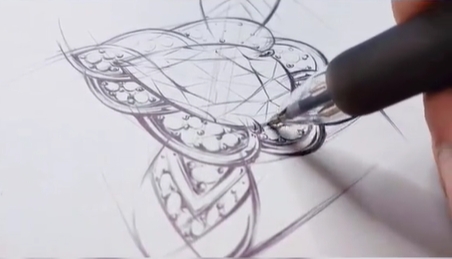

Introduction to Custom Jewelry Manufacturing

In today’s competitive jewelry market, personalization and exclusivity have become key differentiators for brands and independent designers. JINGYING specializes in transforming your unique CAD designs into exquisite gold-plated pendants, offering a seamless bridge between digital concepts and physical luxury products. This comprehensive guide explores our end-to-end manufacturing process, material options, quality standards, and why we stand out as the preferred partner for custom pendant production.

Section 1: The Advantages of CAD-Based Jewelry Production

1.1 Precision Engineering for Complex Designs

Modern jewelry design has been revolutionized by Computer-Aided Design (CAD) technology, which allows for:

- Micron-level accuracy in dimensional specifications

- Perfect symmetry and geometric precision

- Visualization of designs from all angles before production

- Easy modification of designs without physical prototyping costs

1.2 Streamlined Production Workflow

Our CAD-to-production process ensures:

- Faster turnaround times compared to traditional hand-carving methods

- Consistent replication of designs across production batches

- Seamless integration with 3D printing and CNC milling technologies

- Digital archiving of designs for future reproduction

Section 2: JINGYING’s Gold Plating Expertise

2.1 Advanced Plating Techniques

We employ state-of-the-art plating methods including:

- Electroplating with 18k or 24k gold (2-5 microns thickness)

- PVD (Physical Vapor Deposition) coating for enhanced durability

- Multi-layer plating systems for superior wear resistance

- Selective plating techniques for two-tone effects

2.2 Material Options for Base Metals

Clients can choose from:

- Premium brass alloys (lead-free and nickel-free)

- 925 sterling silver

- Stainless steel

- Zinc alloys for lightweight designs

Section 3: The Manufacturing Process Breakdown

3.1 Design Optimization Phase

Our technical team:

- Reviews CAD files for manufacturability

- Suggests design modifications to enhance durability

- Provides DFM (Design for Manufacturing) analysis

- Creates detailed technical drawings for client approval

3.2 Prototyping and Sampling

We offer:

- High-resolution 3D printed prototypes in resin or wax

- Cast metal samples for final approval

- Finish and plating samples for color matching

- Rapid iteration capabilities for design refinement

3.3 Production Execution

Our production workflow includes:

- Precision investment casting using lost-wax method

- CNC machining for architectural designs

- Laser cutting for intricate patterns

- Hand-finishing and polishing by master craftsmen

Section 4: Quality Assurance Protocols

4.1 Material Testing

- XRF analysis for metal composition verification

- Plating thickness measurement with digital micrometers

- Porosity testing for cast items

4.2 Finishing Standards

- 10-stage polishing process for mirror finishes

- Microscopic inspection of all surfaces

- Stone-setting verification under magnification

- Final QC checklist with 25-point inspection

Section 5: Customization Options

5.1 Design Variations

- Minimalist modern styles

- Ornate vintage-inspired pieces

- Architectural geometric designs

- Organic free-form creations

5.2 Finish and Texture Options

- High polish mirror finish

- Matte brushed surfaces

- Hammered textures

- Sandblasted effects

- Antique oxidized detailing

Section 6: Sustainable Manufacturing Practices

6.1 Eco-Friendly Production

- Water-based plating solutions

- Closed-loop water recycling systems

- Solar-powered production facilities

- Recycled metal sourcing programs

6.2 Ethical Business Practices

- Conflict-free material sourcing

- Fair labor certifications

- Transparent pricing models

- Responsible waste management

Section 7: Client Collaboration Process

7.1 Project Initiation

- Design consultation and technical briefing

- Material selection guidance

- MOQ and pricing discussion

- Timeline planning

7.2 Production Management

- Regular progress updates

- Quality checkpoints with client approval

- Flexible order adjustments

- Packaging customization options

Section 8: Global Logistics Solutions

8.1 Shipping and Handling

- Air freight express options (3-5 days)

- Ocean shipping for bulk orders

- Customs clearance assistance

- Insurance coverage options

8.2 After-Sales Support

- Replating services

- Repair and refurbishment

- Inventory management programs

- Seasonal production planning

Conclusion: Why Choose JINGYING for Custom Pendants?

JINGYING combines cutting-edge technology with traditional craftsmanship to deliver:

- Unmatched precision in CAD-based manufacturing

- Luxurious gold plating finishes that endure

- Rigorous quality control standards

- Sustainable and ethical production practices

- Seamless global logistics support

Our commitment to excellence ensures your custom pendant designs are transformed into heirloom-quality jewelry pieces that reflect your unique vision while meeting the highest industry standards. Whether you’re an independent designer, a startup brand, or an established jewelry company, JINGYING provides the technical expertise and creative partnership to bring your pendant concepts to life.