The process of jewelry making is divided into the early stage and the late stage.

The early stage is the design drawing that needs to be discussed with you before it can be formulated

The basic process can be divided into the following four steps:

1. Choose or design the style you like (pendant/ring/earring/bracelet)

2. Choose matching gemstones (type/color/shape)

3. Choose suitable precious metals (platinum/K gold/gold/silver)

4. Estimate the customization cost and processing time

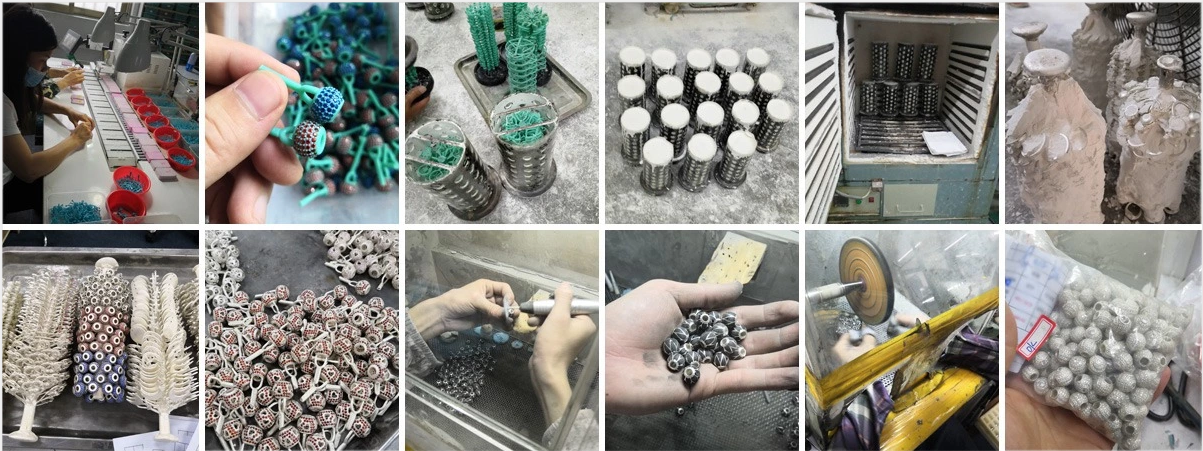

The late stage will be handed over to us and the factory: (Take silver as an example)

1 Concept and design: The designer draws the effect diagram according to the design draft, and uses the drawing software Jewel CAD and PS to draw the sketch on the computer with precise size to complete the initial design drawing.

2 Craftsman carving wax: The jewelry craftsman manually carves the wax plate according to the design drawing and the size of the gemstone, and then uses the lost wax casting method to pour out the silver plate to get the prototype of the jewelry.

Here you may ask, what is lost wax casting? Simply put, it is to wrap the wax model with plaster and reserve a small hole, dry it and then bake it, so that the wax model will be vaporized and evaporated, and the plaster will become the shell, and the inner wall of the shell will leave the negative mold of the wax model. At this time, the molten metal is injected into the shell through the small hole, and the shell is broken after cooling to obtain the required metal casting. It is a metal craft that is not only used in jewelry, but also can be used in various metal devices.

3 Polishing process: Use a polishing machine to polish the jewelry until the surface is flat, smooth and bright.

4 Inlay gemstones.

Finally, finish and polish, so that a piece of jewelry dedicated to you is completed.