Silver jewelry production process

Silver jewelry, the jewelry we wear daily, is loved for its unique luster and diverse styles. However, have you ever wondered how these exquisite silver jewelry are made? Next, we will reveal the complete production process of silver jewelry for you.

1. Silver melting stage

Put silver flakes and broken silver into a crucible and heat them to a specific temperature with the help of charcoal to melt the silver into silver water.

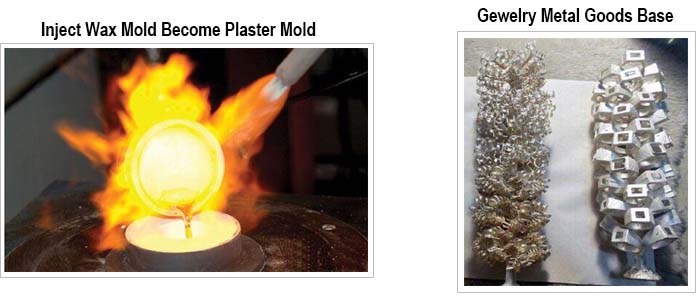

2. Casting process

Pour the molten silver water into the mold and wait for it to cool and solidify to obtain the silver blank.

3. Leaf, strip and wire drawing process

Heat the silver blank according to the production requirements. Through hammering and kneading, the silver blank is shaped into a “leaf”-shaped sheet, and then further rubbed into a “strip”-shaped cylinder. Subsequently, the silver bar is wire-drawn using special tools. This step requires precise control of the temperature. Overheating will easily melt the silver, and insufficient temperature will make it difficult to form. Eventually, these silver sheets, bars and wires will be used to make a variety of silver jewelry, such as silver plaques, silver bells, silver collars, silver bracelets and silver necklaces, depending on their different forms.

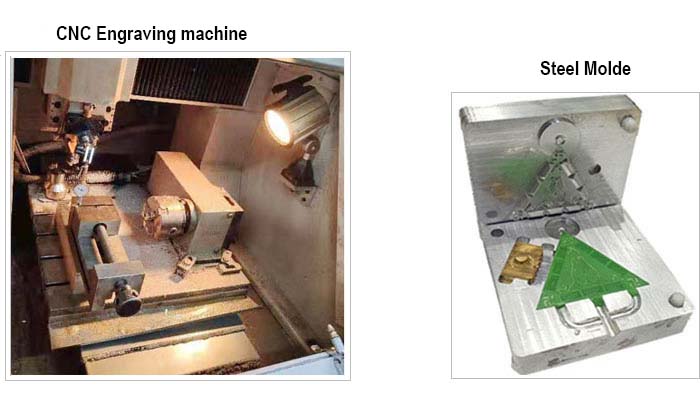

4. Stamping

Place the silver sheet in a tin mold and hammer it to stamp out the basic outline of the silverware. This step is also called “bracketing”.

5. Gluing

Make glue, usually using rosin and oil, and apply it on the wooden board to form a layer about one centimeter thick. Then, bake the glue with charcoal fire, and when it softens, the general shape of the silverware is pressed on the glue board.

6. Engraving patterns

Use various special tools, such as round heads, flat heads, crescent heads, hollow heads and pointed heads, to carefully engrave various exquisite patterns on the silverware. This process is considered the most complicated and technically demanding part of silverware manufacturing. In this process, the craftsman needs to perfectly combine the flower-shaped conception in his mind with the skills in his hands to carve out a moving silver pattern.

7. Precision welding

According to the design of the silverware, each component is finely welded and supplemented with exquisite pattern decoration. During the welding process, by cleverly using boric acid water and welding pieces, with the help of the flame of the kerosene lamp, and with the help of the blowpipe, the temperature is accurately controlled to ensure the perfect presentation of welding.

8. Delicate polishing

Put the silverware on a small copper anvil, and through the fine beating of a small hammer and the clever polishing of a steel file, the surface of the silverware is as smooth as a mirror.

9. Thorough decontamination

Apply the detergent dilute sulfuric acid or alum to the surface of the silverware for in-depth decontamination treatment, thoroughly remove mildew and dirt, and restore the pure essence of the silverware.

10. Careful coloring

Use special pigments and kerosene lamps to accurately apply pigments on the silverware with a small spoon. Then, with the help of the flame of the blowpipe, the silver and pigment are melted together and adhered to the silverware, thus forming a colorful artistic effect.

After ten delicate processes, a piece of pure silver jewelry is finally born. Of course, this is just a simple example of the production process of silver jewelry. For more complex silver jewelry products, the production process will be more complicated.