Introduction

Creating your own sterling silver bracelet is a rewarding and creative process that allows you to craft a unique piece of jewelry. Whether you’re a beginner or an experienced jewelry maker, this guide will walk you through the essential steps, tools, and techniques needed to make a beautiful, high-quality sterling silver bracelet.

Sterling silver is an alloy consisting of 92.5% silver and 7.5% other metals (usually copper) for added strength. It is a popular choice for jewelry due to its durability, shine, and affordability compared to pure silver.

This guide covers:

- Materials and Tools Needed

- Designing Your Bracelet

- Cutting and Shaping the Silver

- Soldering (If Required)

- Filing and Sanding

- Polishing and Finishing

- Adding Clasps and Embellishments

- Caring for Your Sterling Silver Bracelet

By the end, you’ll have the knowledge to create a professional-looking sterling silver bracelet.

1. Materials and Tools Needed

Before starting, gather the necessary materials and tools:

Materials:

- Sterling silver wire or sheet (depending on design)

- Jump rings (for attaching clasps)

- Clasp (lobster, toggle, or magnetic)

- Solder (if joining pieces)

- Flux (for soldering)

- Polishing compounds (rouge or tripoli)

- Patina solution (optional, for antique effects)

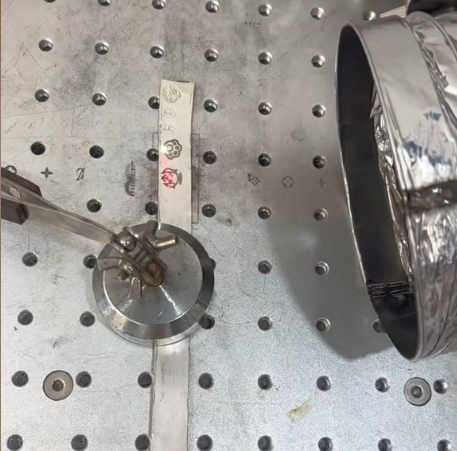

Tools:

- Jewelry saw & blades (for cutting silver)

- Metal files (flat, round, and half-round)

- Sandpaper (various grits: 220 to 2000)

- Bench pin & vise (for stability)

- Soldering torch (butane or propane)

- Third hand or tweezers (for holding pieces)

- Steel block & rawhide mallet (for shaping)

- Polishing wheel or rotary tool

- Ruler & calipers (for measurements)

- Pliers (round-nose, flat-nose, chain-nose)

Having the right tools ensures precision and efficiency in your work.

2. Designing Your Bracelet

Before cutting metal, plan your design:

Bracelet Styles:

- Chain bracelet (made with links)

- Cuff bracelet (solid or open-ended)

- Bangle (rigid, circular)

- Beaded bracelet (silver with gemstones)

Measurement Tips:

- Use a flexible measuring tape to determine wrist size.

- Add ½ inch for comfort (or more for a looser fit).

- Standard bracelet lengths:

- Women: 7–7.5 inches

- Men: 8–8.5 inches

Sketch your design and mark dimensions before proceeding.

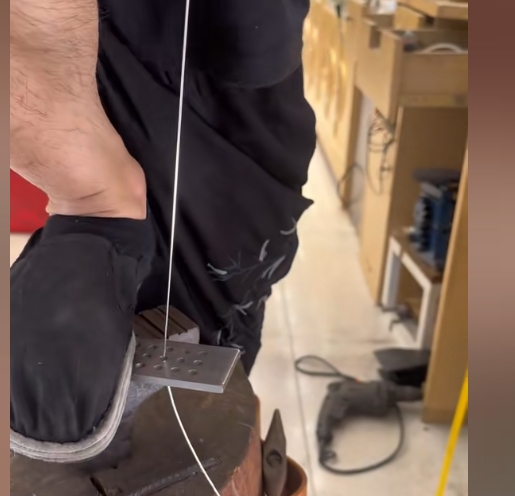

3. Cutting and Shaping the Silver

A. Cutting the Silver

- For wire-based bracelets:

- Measure and mark the desired length.

- Use flush cutters for a clean cut.

- For sheet metal (cuffs or bangles):

B. Shaping the Silver

- For wire: Bend using round-nose pliers or a mandrel.

- For cuffs/bangles:

- Anneal (soften) the silver by heating it with a torch until glowing red, then quench in water.

- Hammer gently on a steel block or mandrel to shape.

4. Soldering (If Required)

Soldering joins metal pieces together.

Steps:

- Clean the surfaces with sandpaper.

- Apply flux to prevent oxidation.

- Place small solder pieces on the joint.

- Heat evenly with a torch until the solder flows.

- Quench in water and pickle (clean with a mild acid solution).

5. Filing and Sanding

Smooth rough edges for a professional finish:

- Filing: Use a flat file for straight edges and a half-round file for curves.

- Sanding: Start with 220-grit sandpaper and progress to 2000-grit for a mirror finish.

6. Polishing and Finishing

- Polishing: Use a rotary tool with a polishing wheel and jeweler’s rouge.

- Optional Patina: Apply liver of sulfur for an antique look, then polish highlights.

7. Adding Clasps and Embellishments

- Attach jump rings using pliers.

- Secure the clasp by opening/closing jump rings properly.

- Add charms or gemstones (if desired).

8. Caring for Your Sterling Silver Bracelet

- Store in an anti-tarnish bag.

- Clean with a silver polishing cloth.

- Avoid exposure to chemicals (perfume, chlorine).

Conclusion

Making a sterling silver bracelet requires patience and precision, but the result is a stunning, handcrafted piece. With practice, you can experiment with different designs and techniques to create unique jewelry.

Now that you have the knowledge, gather your tools and start crafting!