Gold Plated Jewelry Manufacturing: A Deep Dive into the 4 Main Steps

Introduction: The Allure of Gilded Affordability

Gold has captivated humanity for millennia, symbolizing power, wealth, and beauty. However, the prohibitive cost of solid gold makes it inaccessible to many. This is where gold-plated jewelry enters the stage, offering the coveted golden aesthetic at a fraction of the price. It represents a perfect marriage of art, science, and economics, making luxury and versatility accessible to a global market.

Gold-plated jewelry is defined by a specific structure: a base metal core, onto which a thin layer of gold is molecularly bonded through an electrochemical process. The quality and longevity of the final piece are not a matter of chance but are determined by the rigorous adherence to precision and quality control at every stage of its creation.

The journey from a concept to a finished, market-ready piece of gold-plated jewelry is a fascinating and complex one. It can be distilled into four critical, sequential steps: 1) Design and Prototyping, 2) Base Metal Fabrication, 3) Surface Preparation and Plating, and 4) Quality Control, Finishing, and Packaging. Each step is a world of its own, encompassing traditional craftsmanship, cutting-edge technology, and intricate chemical engineering. This article will provide a comprehensive exploration of each of these four main steps, revealing the meticulous effort that transforms raw materials into objects of desire.

Step 1: Design and Prototyping – The Blueprint of Beauty

Before any metal is touched or any chemical bath is prepared, every piece of jewelry begins as an idea. The Design and Prototyping phase is the foundational stage where creativity is harnessed, concepts are validated, and the blueprint for mass production is established.

1.1 Conceptualization and Sketching

The process ignites with inspiration. Designers draw influence from trends forecasted by industry authorities like the Pantone Color Institute, historical art movements, nature, architecture, and cultural motifs. This initial stage is highly fluid and creative:

- Hand Sketching: Many designers start with traditional pencil-and-paper sketches. This allows for rapid exploration of forms, proportions, and stylistic elements without the constraints of software. Multiple iterations are created, refined, and narrowed down.

- Digital Design: Increasingly, the initial concept is born digitally using specialized software such as Computer-Aided Design (CAD) programs like Rhino 3D, Matrix, or ZBrush. Digital design offers immense advantages from the outset, allowing for perfect symmetry, easy manipulation of complex forms, and the creation of technical drawings.

1.2 Technical Design and CAD Modeling

Once a sketch is approved, it transitions into a precise, three-dimensional digital model. This is where the artist’s vision is translated into an engineer’s blueprint.

- Precision Modeling: A CAD specialist, often called a digital jeweler, builds the model from the ground up. Every curve, prong, groove, and surface texture is defined with mathematical accuracy.

- Engineering for Wearability: The model is not just about aesthetics; it must be engineered for real-world use. The designer must consider:

- Structural Integrity: Will that delicate filigree snap? Is the bail of the pendant strong enough to hold a chain?

- Comfort and Function: How does a ring sit on the finger? Is the clasp mechanism reliable and easy to use?

- Plating Considerations: The design must account for the plating process. Sharp, hard edges can lead to uneven plating thickness due to the “edge effect,” where current density is higher. Deep, narrow crevices might trap plating solutions and be difficult to rinse, leading to corrosion later. A good CAD designer will incorporate radii and smooth transitions to ensure uniform plating.

1.3 Prototyping: Bringing the Digital to Life

A CAD model on a screen can be deceptive. A physical prototype is essential to assess the design’s true form, feel, and function. Two primary technologies dominate this stage:

- 3D Printing (Additive Manufacturing): This is the most common method today. The CAD file is sent to a 3D printer, which builds the model layer by layer out of a UV-sensitive liquid resin (SLA – Stereolithography) or a wax-like material (PolyJet). This “print” is a highly accurate, tangible representation of the final design.

- Wax Molding and Carving: For very traditional or highly organic designs, a master model may still be hand-carved from a block of jeweler’s wax using specialized tools. This is a skilled artisanal process.

The resulting 3D print or wax model is known as the prototype or pattern.

1.4 Sampling and Validation

The prototype is used to create a single metal sample, typically in brass or silver, via the casting process (detailed in the next step). This sample is crucial for:

- Design Validation: The team holds, wears, and tests the sample. Does it look as expected? Is it comfortable? Does the mechanism work?

- Market Testing: The sample may be shown to focus groups or key buyers to gauge market reception.

- Manufacturing Assessment: Production engineers examine the sample to identify any potential manufacturing challenges before full-scale production begins.

Feedback from this stage is incorporated, and the CAD model is refined in an iterative loop until the perfect master model is achieved. This master model is the physical embodiment of the design and will be used to create the molds for mass production.

Step 2: Base Metal Fabrication – Creating the Canvas

The base metal forms the structural core of the jewelry, its “canvas.” The choice of metal and the method of fabrication are critical, as they determine the piece’s strength, weight, cost, and how it will interact with the plating process.

2.1 Choice of Base Metals

Not all metals are suitable for gold plating. The selected metal must be affordable, durable, and possess good electroplating properties.

- Brass (Copper-Zinc Alloy): The most popular choice for gold-plated jewelry. It’s relatively inexpensive, easy to cast and machine, and has a warm, yellow color that provides an excellent underlying base for gold plating. If the plating wears thin, the brass underneath does not create a stark, unattractive contrast.

- Copper: Used for its excellent electrical conductivity and malleability. It is often used as an underlying layer for other base metals or for specific styles. Pure copper is relatively soft.

- Stainless Steel: Gaining popularity for its exceptional strength and resistance to corrosion. It is hypoallergenic, making it ideal for earring posts and piercing jewelry. However, it requires specialized plating techniques to ensure the gold layer adheres properly.

- Zinc Alloys (e.g., Zamak): Often used for intricate, press-fit findings and cost-effective fashion jewelry due to their excellent die-casting properties. They can be brittle and must be plated with care to prevent corrosion.

2.2 Manufacturing Techniques

The method used to shape the base metal depends on the design’s complexity, volume, and cost considerations.

- A. Casting: The Method for Complexity

Casting is the predominant method for creating detailed, three-dimensional jewelry components like pendants, charms, and ring bands with complex designs.- Tree Building: The approved wax or resin prototypes are attached to a central wax “tree,” creating a structure that resembles a chandelier. A single tree can hold dozens or even hundreds of identical patterns.

- Investing: The tree is placed inside a steel flask, and a liquid plaster-like material, called investment, is poured around it. The investment sets into a hard, heat-resistant mold.

- Burnout: The flask is placed in a kiln and heated to a high temperature. This process melts and vaporizes the wax (“lost-wax casting”), leaving behind a perfect, hollow cavity in the shape of the jewelry pieces within the hardened investment.

- Melting and Pouring: The chosen base metal is melted in a crucible at temperatures exceeding 1000°C. Using a centrifugal casting machine or vacuum assist, the molten metal is forced into the hollow cavities of the investment mold.

- Quenching and Devesting: Once the metal has solidified, the flask is cooled and placed in water. The investment dissolves away, revealing the metal “tree” now composed of solid jewelry pieces.

- Cutting Off: The individual pieces, called castings, are carefully cut from the tree using saws.

- B. Stamping and Die-Striking: The Method for Simplicity and Volume

This method is used for simpler, flatter, or more uniform designs like chain links, simple hoop earrings, and coin-like pendants.- Die Creation: A custom steel tool, called a die, is fabricated. It consists of two halves—one with a raised design (the punch) and one with a recessed design (the cavity)—that fit together perfectly.

- The Stamping Process: A sheet of base metal is placed between the two halves of the die. A powerful hydraulic or mechanical press forces the dies together with immense pressure, shearing the metal and impressing the design into it simultaneously.

- Advantages: Stamping is extremely fast and cost-effective for high-volume production. The resulting pieces are also stronger and denser than cast pieces as the metal’s grain structure is compressed.

- C. Wire Drawing and Chain Making

Chains are a staple of jewelry, and their manufacture is a specialized field.- Wire Drawing: Metal rods are pulled through a series of progressively smaller dies to achieve the desired wire thickness.

- Chain Assembly: This can be done by machine for simple chains like rope or cable chains, or by hand for more complex styles like Figaro or Byzantine chains. Links are formed, connected, and often soldered closed for strength.

2.3 The First Steps of Finishing: Pre-Plating Assembly

After fabrication, the raw components are rough and require initial finishing.

- Filing and Deburring: Rough edges, known as sprues (from casting) and burrs (from stamping), are manually filed away.

- Tumbling: Components are placed in a rotating barrel (a tumbler) with an abrasive media, water, and a burnishing compound. This process work-hardens the metal, smooths surfaces, and produces a uniform, satin-like preliminary finish.

- Soldering: If the piece has multiple components (e.g., a pendant bail soldered to the pendant, or a ring shank soldered to a setting), this is done by a skilled artisan using a torch and a solder with a lower melting point than the base metal.

At the end of this step, we have a fully formed, assembled, and smoothed base metal item, ready for the transformative process that will give it the iconic appearance of gold.

Step 3: Surface Preparation and Plating – The Alchemical Transformation

This is the most technically complex and chemically sensitive stage of the entire process. The success of the gold plating—its adhesion, brightness, and durability—is almost entirely dependent on the rigor of the preparation that precedes it. The principle is simple: a perfectly clean surface is essential for a perfect plate.

3.1 Surface Preparation: The Unseen Key to Quality

This multi-stage cleaning process is designed to remove every conceivable contaminant from the base metal surface.

- Solvent Cleaning: An initial degreasing bath in an organic solvent or alkaline solution removes oils, fingerprints, and waxes from handling and previous processes.

- Electrocleaning: The jewelry is submerged in an alkaline, electrically charged bath. It acts as the cathode (negative terminal), causing hydrogen gas to bubble vigorously from its surface. This electrochemical reaction scrubs away microscopic impurities and oxides.

- Acid Pickling: The pieces are immersed in a mild acid solution (like sulfuric or hydrochloric acid). This etches the surface microscopically, removing any remaining oxide layers and providing a slightly textured surface for superior mechanical adhesion of the plating. For zinc-based alloys, a much milder acid is used to prevent corrosion.

- Rinsing: Perhaps the most critical and repeated step in the entire process. After every single chemical bath, the jewelry must be thoroughly rinsed in deionized water to prevent contaminating the next solution. Inadequate rinsing is a primary cause of plating failure.

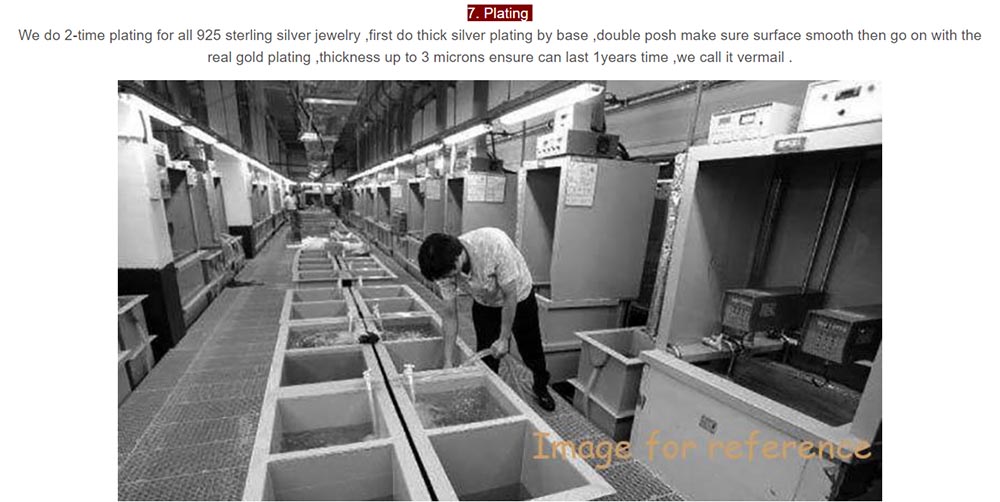

3.2 The Electroplating Process: Building the Layers

After preparation, the jewelry is ready for plating. The fundamental setup involves an electrolyte solution containing dissolved gold salts, an anode (often an inert material like titanium coated with platinum), and the jewelry piece acting as the cathode. When a direct current is applied, gold ions (Au+) are attracted to the negatively charged jewelry and are reduced to metallic gold, forming a coherent layer on its surface.

However, plating pure gold directly onto base metals is rarely done. A multi-layer approach is used to enhance performance and appearance.

- Step 3.2.1: The Strike Layer (Barrier Plating)

The first layer deposited is a “strike.” This is a thin, dense layer of a metal that adheres well to both the base metal and subsequent layers. Nickel is the most common strike layer. It provides a brilliant, white underlying base that enhances the reflectivity and color of the final gold layer. Crucially, it acts as a barrier, preventing atoms from the base metal (like copper or zinc) from migrating through the gold layer over time, which can cause tarnishing or discoloration. Due to nickel’s potential to cause allergic reactions, many manufacturers now use hypoallergenic alternatives like palladium-nickel or a copper strike for certain base metals. - Step 3.2.2: The Gold Plating Layer

After the strike layer, the piece is transferred to the final gold plating bath. The characteristics of this bath determine the final product’s properties.- Gold Content: The bath uses potassium gold cyanide as the primary source of gold ions. The purity of the gold in the bath can be adjusted to create different karat colors (e.g., 14k, 18k, 24k).

- Color and Alloying: To achieve different gold colors, other metals are added to the bath:

- Yellow Gold: Pure 24k gold or a high-karat alloy.

- White Gold: Alloyed with palladium or nickel (though nickel is being phased out).

- Rose Gold: Alloyed with a higher proportion of copper.

- Brighteners and Levelers: Proprietary organic additives are included in the bath. These chemicals help produce a brilliant, mirror-bright finish by promoting a uniform deposition of gold atoms, filling in microscopic valleys and smoothing the surface.

3.3 Determining Plating Thickness

The thickness of the gold layer is a key quality determinant and is directly controlled by:

- Current Density: The amount of electrical current per unit area.

- Time: The duration the jewelry remains in the bath.

- Solution Concentration: The concentration of gold ions in the electrolyte.

Thickness is measured in microns (µm) or, more commonly for jewelry, in micro-inches (µ”). The quality of gold-plated jewelry is often described by its ”gold thickness” and its ”gold fineness” (e.g., “2.5 microns of 18k gold”).

Common industry classifications based on thickness include:

- Class 1, Heavy Gold Electroplate/HEGP: (≥ 2.5 µ” or 0.1 µm) A durable, high-quality plating for items intended for regular wear.

- Gold Plated/GP: (≥ 0.7 µ” or 0.025 µm) The standard for quality fashion jewelry.

- Gold Flash/GF: (< 0.7 µ”) A very thin, decorative layer with limited durability, typical for low-cost, disposable fashion items.

After the plating is complete, a final, ultra-thin layer of a clear, protective lacquer or a hard coating like rhodium (for white gold) may be applied to certain areas to prevent tarnishing and enhance scratch resistance.

Step 4: Quality Control, Finishing, and Packaging – The Final Curation

The journey concludes with a series of meticulous checks and enhancements that prepare the jewelry for its debut.

4.1 Rigorous Quality Control (QC)

Every piece must pass through a stringent QC process before it can be approved for sale.

- Visual Inspection: Inspectors examine pieces under bright, magnified lights for defects such as:

- Plating Flaws: Peeling, blistering, discoloration, or uneven color.

- Surface Imperfections: Scratches, pits, or roughness.

- Construction Defects: Weak solder joints, misaligned components, or non-functioning clasps.

- Thickness Verification: For high-value batches, a X-Ray Fluorescence (XRF) spectrometer is used. This non-destructive device bombards the item with X-rays and measures the fluorescent radiation emitted to provide an exact reading of the plating thickness and composition.

- Adhesion Tests: Samples from a batch may be subjected to tests like the “tape test” (applying and removing adhesive tape to see if plating comes off) or heat-quench tests to ensure the plating is properly bonded.

- Durability Testing: Samples may be tested for corrosion resistance using a salt spray chamber to simulate accelerated aging and wear.

4.2 Final Finishing and Setting

Pieces that pass QC may undergo final aesthetic touches.

- Polishing and Buffing: While the plating bath provides brightness, a final polish with soft wheels and fine compounds can enhance the luster to a high shine.

- Stone Setting: If the design includes gemstones (e.g., cubic zirconia, synthetic crystals, or natural stones), they are set at this stage. Skilled setters use tools to carefully secure the stones in their settings without damaging the delicate gold plating.

- Oxidizing: For an antique or vintage look, a chemical solution may be applied to recessed areas to darken them, creating contrast and making the design details “pop.”

4.3 Packaging and Presentation

The unboxing experience is part of the product. Jewelry is carefully placed in polybags to prevent scratching, tagged with relevant legal disclosures (e.g., “Gold Plated”), and presented in branded boxes or pouches. This not only protects the product during shipping but also enhances the perceived value and provides a satisfying customer experience.

Conclusion

The creation of a piece of gold-plated jewelry is a remarkable synthesis of artistic vision, metallurgical science, and precision engineering. The four main steps—Design and Prototyping, Base Metal Fabrication, Surface Preparation and Plating, and Quality Control and Finishing—form an interconnected chain where excellence at each stage is non-negotiable.

Understanding this process demystifies the product and empowers both retailers and consumers to appreciate the value proposition of well-made gold-plated jewelry. It is not merely “cheap jewelry,” but rather the result of a sophisticated manufacturing process designed to deliver the timeless beauty of gold in a durable, accessible, and versatile form. From the designer’s first sketch to the final quality control check, every action is dedicated to ensuring that the finished piece not only captures the light but also captures the heart of its wearer.