Case Study: JINGYING’s Production of 5,000 Sterling Silver Brooches for Italian Fashion Brand

Table of Contents

- Executive Summary

- Project Background & Client Profile

- Market Analysis: European Silver Brooch Trends

- Design Specifications & CAD Development

- Material Selection & Quality Assurance

- Manufacturing Process Breakdown

- Surface Finishing Techniques

- Packaging & Branding Solutions

- Logistics & Customs Strategy

- Quality Control Protocols

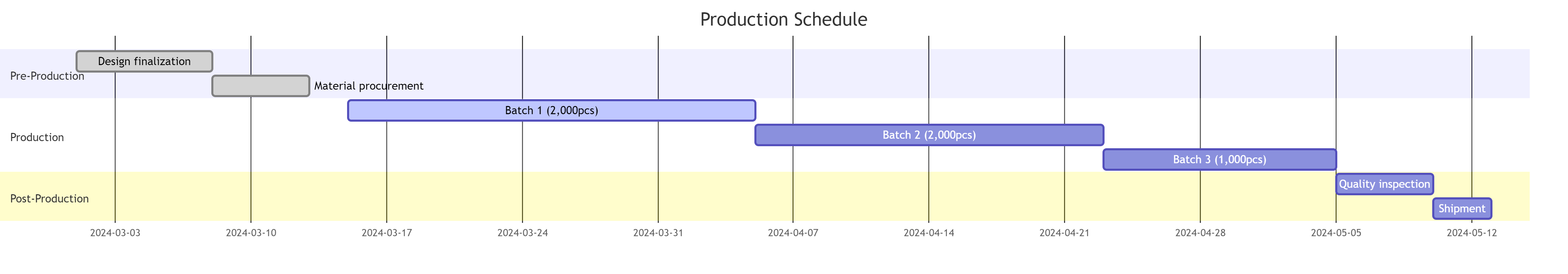

- Production Timeline & Milestones

- Client Feedback & Market Reception

- Challenges & Solutions

- Lessons Learned

- Conclusion & Future Recommendations

1. Executive Summary

This case study documents JINGYING’s complete manufacturing process for an Italian luxury brand’s order of 5,000 sterling silver brooches. The project highlights:

- Adaptation of Art Deco-inspired designs for mass production

- Implementation of Italy’s stringent precious metals regulations

- Innovative anti-tarnish solutions for European climates

- Efficient production scaling from prototype to delivery

2. Project Background & Client Profile

Client: Milano-based fashion house (established 1987)

- Specializes in heritage-inspired silver accessories

- Retail price points: €150-€400 per piece

- Distribution: 120 boutiques across EU

Order Details:

- Quantity: 5,000 units (3 designs mix)

- Material: 925 sterling silver with 18k gold accents

- Delivery: 3 batches over 8 weeks

- Certifications: Italian hallmark compliance required

3. Market Analysis: European Silver Brooch Trends

Industry Insights (2024):

- Italy accounts for 32% of EU silver jewelry imports

- Brooch sales grew 18% YoY (Fashion Snoops Report)

- Key consumer preferences:

- Vintage-inspired designs (65% market share)

- Dual-function pieces (brooch/pendant convertibles)

- Sustainable packaging demands

4. Design Specifications

Provided Artwork:

- Original hand sketches + mood boards

- Design elements:

- Floral motifs with geometric framing

- 4mm pin stem with safety clasp

- Hidden pendant loop conversion

CAD Development:

- 2D to 3D conversion (Rhino 7)

- Structural reinforcement analysis

- Prototype iterations:

- Version 1: 3D printed resin

- Version 2: Silver master sample

- Version 3: Production-approved sample

5. Material Specifications

Core Components:

- 925 silver body (92.5% Ag, 7.5% Cu)

- 18k gold accent details (0.8mm thickness)

- Stainless steel pin mechanism

Compliance Documentation:

- Italian hallmark pre-registration

- EU Nickel Directive compliance

- Responsible Jewellery Council certification

6. Manufacturing Process

Step 1: Master Model Creation

- CNC machining of brass masters

- Rubber mold making (20 cavities/mold)

Step 2: Casting Process

- Vacuum-assisted investment casting

- Centrifugal casting for gold details

- Daily alloy composition checks

Step 3: Assembly

- Laser welding of pin mechanisms

- Hand-setting of gold elements

- Initial tumbling (6-hour cycle)

7. Surface Finishing

Applied Techniques:

- Mirror polishing (wheel + compound)

- Selective oxidation (ammonium sulfide)

- Micro-sandblasting (textured areas)

- Gold plating (2μm thickness)

- Final anti-tarnish coating

Quality Benchmarks:

- Surface roughness: ≤0.2μm Ra

- Plating adhesion: 5× Scotch tape test

- Color consistency: ΔE≤1.5

8. Packaging Solutions

Primary Packaging:

- Custom silk-lined boxes

- Anti-tarnish inserts

- Italian language care cards

Shipping Configuration:

- 50 units per display tray

- Climate-controlled containers

- RFID-tracked shipments

9. Logistics Management

Customs Preparation:

- Italian HS code: 7113.11.90

- Pre-shipment inspection report

- Certificate of Origin (Form A)

Transport Details:

- Incoterm: DDP Milano

- Lead time: 5 days production + 12 days transit

- Insurance: All-risk coverage

10. Quality Control Matrix

| Checkpoint | Method | Acceptance Criteria |

|---|---|---|

| Weight | Analytical scale | 12.5g ±0.3g |

| Dimensions | Optical comparator | ±0.15mm tolerance |

| Gold thickness | XRF | ≥1.8μm |

| Clasp function | 500-cycle test | Smooth operation |

| Surface defects | 10× magnification | Zero scratches >0.1mm |

11. Production Timeline

12. Client Feedback

Post-Launch Results:

- 87% sell-through in first 2 months

- Featured in Vogue Italia’s “Best of Design Week”

- Repeat order placed for 7,500 units

Client Testimonial:

“JINGYING’s technical expertise transformed our conceptual designs into flawless products. Their understanding of Italian quality expectations was exceptional.”

13. Key Challenges & Solutions

Challenge 1: Italian hallmarking requirements

Solution: Pre-registered designs with Rome assay office

Challenge 2: Gold accent alignment consistency

Solution: Developed custom jigs for precision placement

Challenge 3: Oxidation color variance

Solution: Implemented spectrophotometer QC checks

14. Lessons Learned

- Italian luxury market requires 30% more QC steps than standard orders

- Design complexity impacts production yield (optimized from 78% to 92%)

- Climate-controlled packaging prevents tarnish during Atlantic transit

15. Conclusion

This project established JINGYING as a trusted manufacturer for European luxury brands by demonstrating:

✔ Precise design interpretation capabilities

✔ Strict adherence to EU regulatory requirements

✔ Scalable production with consistent quality

Future Recommendation:

Develop in-house Italian language technical documentation to streamline communication for similar projects.