JINGYING :the OEM jewelry factory of the rose gold plated earring with Cubic Zirconia Jewelry

JINGYING :the OEM jewelry factory of the rose gold plated earring with Cubic Zirconia Jewelry

LET’S GET STARTED : mo@kingjy.com

JINGYING: The Pinnacle of OEM Excellence in Rose Gold Plated Cubic Zirconia Earrings

In the dynamic world of fashion jewelry, few combinations capture the essence of contemporary elegance as perfectly as the warm, romantic hue of rose gold set against the brilliant sparkle of cubic zirconia. This duo has dominated trends, from the runways of Paris to the red carpets of Hollywood, becoming a staple in the collections of discerning consumers worldwide. However, behind every stunning pair of rose gold plated CZ earrings that graces the market lies a critical decision: the choice of manufacturer. For brands, retailers, and startups seeking to capitalize on this enduring trend, the partnership with an Original Equipment Manufacturer (OEM) is not just a transaction; it is the foundational step that determines product quality, brand reputation, and market success.

This article delves deep into the world of JINGYING, positioning it as the quintessential OEM partner for the creation of exceptional rose gold plated earrings with cubic zirconia. We will explore the anatomy of these exquisite accessories, deconstruct the OEM process, and illuminate why JINGYING’s expertise, technological prowess, and unwavering commitment to quality make it the definitive choice for businesses looking to craft not just jewelry, but legacies.

Part 1: The Unending Allure of Rose Gold and Cubic Zirconia

To understand JINGYING’s specialization, one must first appreciate the raw materials that form the heart of its craft.

The Romance of Rose Gold:

Rose gold is not a pure metal but a beautiful alloy, traditionally crafted by blending yellow gold with copper and a touch of silver. The copper content is what imparts its distinctive pinkish-red hue, a color often associated with love, compassion, and timeless style. Its popularity has surged in the 21st century because it is remarkably flattering on a wide range of skin tones, offering a warmth that white gold can lack and a uniqueness that sets it apart from traditional yellow gold. In the context of plating, achieving a consistent, authentic, and durable rose gold color is a technical art in itself—an art that JINGYING has mastered.

The Democratic Diamond: Cubic Zirconia:

Cubic Zirconia (CZ) is the crystalline form of zirconium dioxide, a lab-created marvel that rivals natural diamonds in brilliance and clarity. Its key properties make it ideal for high-quality fashion jewelry:

- Exceptional Brilliance: With a refractive index of approximately 2.15-2.18, high-quality CZ disperses light into spectacular flashes of color, often exhibiting even more “fire” than a diamond.

- Impeccable Clarity: Virtually flawless, CZ offers a level of perfection that is exorbitantly expensive in natural gemstones.

- Impressive Durability: Ranking 8-8.5 on the Mohs scale of hardness, CZ is durable enough for daily wear, resisting scratches and maintaining its polish over time.

- Affordability and Ethics: As a lab-grown stone, CZ is both accessible and conflict-free, allowing for the creation of luxurious, statement pieces without the prohibitive cost or ethical concerns.

The marriage of rose gold’s warm elegance with CZ’s dazzling fire creates a product that is both emotionally resonant and visually captivating. It is this very synergy that JINGYING leverages to help its clients build powerful and profitable jewelry collections.

Part 2: JINGYING OEM – The Architect of Your Vision

An OEM manufacturer like JINGYING is not merely a factory that follows orders. It is an integrated partner that provides end-to-end services, from initial concept to final, packaged product. For a brand, this means accessing a reservoir of expertise without the capital investment in machinery, labor, and R&D.

The Core Philosophy of JINGYING:

JINGYING operates on a philosophy of collaborative innovation. They understand that each client, from an established luxury house to an emerging e-commerce startup, has a unique vision and market position. Their role is to become an extension of the client’s team, offering technical guidance, creative problem-solving, and industrial capability to transform a abstract idea into a tangible, market-ready product.

Why the OEM Model is Crucial for Success:

- Focus on Core Competencies: Brands can focus on what they do best: marketing, branding, and sales, while leaving the complex manufacturing to the experts.

- Cost-Effectiveness: Eliminates the need for massive capital expenditure in production facilities, raw material bulk purchasing, and specialized labor.

- Scalability and Flexibility: JINGYING can handle orders of varying quantities, allowing brands to test the market with a small batch or launch a full-scale collection with equal efficiency.

- Access to Advanced Technology and Expertise: Clients immediately benefit from state-of-the-art equipment and years of specialized knowledge in working with precious metals and gemstones.

Part 3: The JINGYING Advantage – A Deep Dive into Specialized Capabilities

What truly differentiates JINGYING in the crowded field of jewelry manufacturing? It is a combination of meticulous processes, advanced technology, and an uncompromising commitment to quality.

A. Mastery in Metalwork: The Science of Rose Gold Plating

The term “rose gold plated” can vary wildly in quality. JINGYING ensures its plating is superior through a controlled, multi-stage process.

- Base Metal Selection: The foundation of any great plated piece is the base metal. JINGYING typically uses high-quality brass or sterling silver (925). Sterling silver is preferred for its hypoallergenic properties and superior feel, creating a premium product for “gold vermeil” – a thick layer of rose gold over sterling silver.

- Meticulous Surface Preparation: Before any plating occurs, the base metal components are polished to a mirror finish. Any imperfection on the base will be amplified by the plating, so this step is critical. The pieces are then thoroughly cleaned and degreased in an ultrasonic bath to ensure perfect adhesion.

- The Electroplating Process: The pieces are submerged in an electrolyte solution containing ions of the plating metals. For rose gold, this is a precise blend of gold, copper, and sometimes a hint of silver. By passing an electric current through the solution, these metal ions are bonded to the surface of the base metal. JINGYING’s expertise lies in controlling:

- Current Density: Affects the uniformity and texture of the plate.

- Solution Chemistry: The exact formula determines the hue of the rose gold, from a subtle pink to a deep, coppery rose.

- Plating Duration: This directly controls the thickness of the plating layer.

- Plating Thickness – The Mark of Quality: JINGYING offers different tiers of plating thickness to suit client needs and price points. For vermeil, they adhere to the strict standard of a minimum of 2.5 microns of gold plating over sterling silver. A thicker plate, such as 3-5 microns, significantly enhances durability and tarnish resistance, ensuring the earrings retain their warm glow for years with proper care.

- Post-Plating Treatment: After plating, pieces are often treated with a protective anti-tarnish coating to further extend their lifespan and beauty.

B. The Art of Stone Selection and Setting: Maximizing CZ’s Potential

Not all CZ is created equal. JINGYING’s commitment to brilliance begins with the stones themselves.

- Grading the CZ: They utilize high-grade, precision-cut cubic zirconia. These stones are selected based on their:

- Cut: The precision of the faceting. A perfect cut ensures optimal light performance, resulting in maximum sparkle. JINGYING uses stones with excellent symmetry and polish.

- Color: The best clear CZ is graded as “White A” or “D-E” color, meaning it is completely colorless, mimicking the highest grade of diamonds.

- Clarity: The stones are virtually flawless, with no visible inclusions or cloudiness.

- Advanced Setting Techniques: The setting is what secures the stone and frames its beauty. JINGYING’s master setters are proficient in all classic and contemporary styles:

- Prong Setting: Using 3, 4, or 6 delicate metal claws to hold the CZ, allowing the maximum amount of light to enter from all angles. Perfect for showcasing solitaire stones.

- Bezel Setting: A sleek, modern rim of metal encircles the stone, offering superior security and a smooth, contemporary look.

- Pavé Setting (from the French for “paved”): A technique where the metal surface is “paved” with multiple small CZs set closely together, creating a continuous surface of dazzling sparkle. This requires immense skill to ensure each stone is level and secure.

- Channel Setting: Stones are set into a linear channel between two metal walls, creating a smooth, flush look ideal for geometric designs or the edges of a stud earring.

- Halo Setting: A larger center CZ is surrounded by a “halo” of smaller melee stones, dramatically increasing the perceived size and brilliance of the central stone.

C. The Technological Backbone: From CAD to Finished Product

JINGYING seamlessly blends traditional craftsmanship with cutting-edge technology.

- Computer-Aided Design (CAD): The client’s idea, whether a sketch or a description, is transformed into a precise 3D digital model by JINGYING’s design engineers. This model allows for perfect visualization of proportions, stone placement, and structural integrity. Clients can review this model from every angle and request adjustments before a single gram of metal is used.

- Photorealistic Rendering: From the CAD file, JINGYING can generate stunningly realistic images of the final product, complete with the rose gold finish and CZ sparkle. This is an invaluable tool for marketing and pre-sales.

- Rapid Prototyping (3D Printing): For new or complex designs, a physical prototype can be 3D printed in resin. This allows the client to feel the weight, size, and ergonomics of the earring, ensuring it is perfect before mass production begins.

- Precision Manufacturing: The approved CAD file drives computer-controlled milling and casting machines, ensuring every component is produced with micron-level accuracy, guaranteeing consistency across every pair in the production run.

Part 4: The OEM Journey – A Collaborative Process from Concept to Carton

Engaging with JINGYING is a structured, transparent, and collaborative process designed to minimize risk and maximize success.

Phase 1: Discovery and Consultation

It begins with a conversation. JINGYING’s project managers and designers work with the client to understand their brand identity, target market, budget, and vision. They provide expert advice on design feasibility, material choices, and cost-effective manufacturing strategies.

Phase 2: Design and Development

- CAD Modeling: Based on the brief, the CAD team creates the initial 3D model.

- Client Review and Revision: The client reviews the model and rendering, and JINGYING makes revisions until the design is fully approved.

- Prototyping (Optional): A sample is 3D printed for physical approval.

Phase 3: Production and Quality Assurance

This is where the approved design comes to life.

- Tooling and Molding: Necessary molds and tools are created for casting.

- Casting: The base metal is cast into the shapes of the earring components.

- Pre-polishing and Assembly: Cast pieces are cleaned, polished, and assembled (e.g., posts are welded to stud backs).

- Plating: The components undergo the precise rose gold electroplating process.

- Stone Setting: Master setters carefully place and secure each CZ stone.

- Final Polishing and Rhodium Plating (if needed): For an extra bright and tarnish-resistant finish on white gold plating, a rhodium top coat may be applied. For rose gold, this step is omitted to preserve the color.

Phase 4: Stringent Quality Control

Every single pair of earrings undergoes a multi-point inspection:

- Plating Quality: Checked for color consistency, thickness, and absence of peeling or discoloration.

- Stone Check: Each CZ is inspected for security, absence of damage, and cleanliness (free of glue or residue).

- Metal Finish: Surfaces are checked for smoothness, polish, and absence of sharp edges.

- Functionality: Earring posts, backs (e.g., friction backs, screw backs, leverbacks) are tested for security and ease of use.

- Overall Aesthetics: The final product is compared against the approved sample to ensure a perfect match.

Phase 5: Packaging and Delivery

JINGYING offers custom packaging solutions. Earrings can be fitted into custom-branded boxes, pouches, or display cards. They are then securely packed and shipped to the client’s specified destination, ready for market.

Part 5: A Universe of Designs: The Rose Gold CZ Earring Portfolio

JINGYING’s capabilities allow for the creation of an endless array of earring styles, catering to every trend and customer preference.

- Stud Earrings: The timeless classic. From simple solitaires and multi-stone clusters to floral motifs and geometric shapes, all enhanced by the rose gold frame.

- Hoop Earrings: From delicate huggies that cling to the earlobe to large, statement-making hoops adorned with pavé CZ or accent stones.

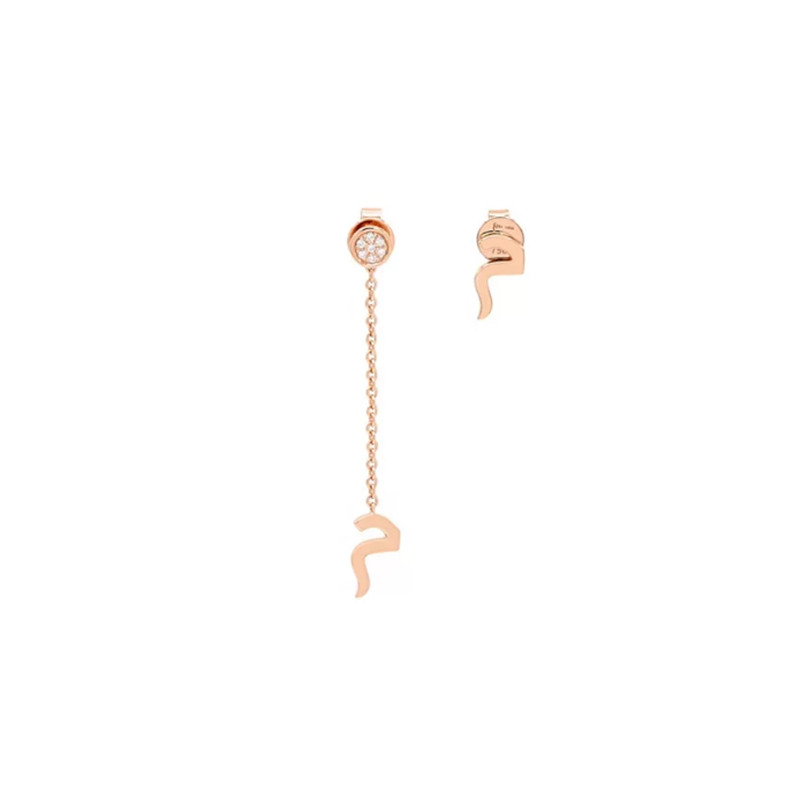

- Drop and Dangle Earrings: Designs that bring movement and drama. This can include elegant chandeliers, minimalist geometric drops, or romantic designs featuring pear-shaped and round CZs.

- Ear Jackets and Threaders: Contemporary styles that offer a fashion-forward look, often featuring a decorative element that dangles behind the earlobe.

- Custom Shapes and Signature Styles: JINGYING excels at bringing unique, brand-defining designs to life, whether it’s a company logo, a symbolic shape, or an entirely new architectural form.

Part 6: Beyond Manufacturing: JINGYING as a Strategic Partner

The relationship with JINGYING often extends beyond a single production run. They act as a strategic partner for business growth.

- Market Intelligence: With their finger on the pulse of the industry, they can advise on trending styles, materials, and finishes.

- Value Engineering: They can suggest design modifications that reduce cost without compromising on aesthetics or quality.

- Supply Chain Reliability: Their established supply chains for metals and CZ stones ensure stability and timely production, even in volatile markets.

- Support for Startups: They provide guidance and scalable solutions for emerging brands, helping them navigate the complexities of jewelry production.

Conclusion: Forging Legacies in Rose Gold and Brilliance

In the competitive landscape of fashion jewelry, the choice of an OEM manufacturer is the most critical decision a brand can make. It is a choice that dictates quality, defines brand perception, and ultimately, determines customer satisfaction. JINGYING, with its sophisticated mastery of rose gold plating, its unwavering standards for cubic zirconia quality, its seamless integration of technology and craftsmanship, and its client-centric OEM process, stands as a beacon of excellence.

For any brand aspiring to create a collection of rose gold plated cubic zirconia earrings that resonates with quality, beauty, and value, the path forward is clear. Partnering with JINGYING is not merely about outsourcing production; it is about investing in a collaborative relationship that transforms creative vision into commercial triumph. It is about offering customers not just an accessory, but a piece of meticulously crafted elegance they will cherish. In the alchemy that turns metal and stone into objects of desire, JINGYING is the proven master.