Customize Your Own 925 Earrings at JINGYING Jewelry OEM manufacturer

Customize Your Own 925 Earrings at JINGYING Jewelry OEM manufacturer

LET’S GET STARTED : mo@kingjy.com

The Ultimate Guide to Customizing Your Own 925 Sterling Silver Earrings with JINGYING Jewelry OEM

The world of jewelry is profoundly personal. It’s a domain where style meets sentiment, where fashion intertwines with identity. While off-the-shelf pieces have their appeal, there is an unparalleled magic in wearing something conceived from your own vision—a design that exists nowhere else in the world. This is the promise of customization, and for businesses, brands, and even individual designers, this journey begins with the right manufacturing partner.

This guide is dedicated to unraveling the intricate, exciting, and ultimately rewarding process of creating your own line of 925 sterling silver earrings through a professional Original Equipment Manufacturer (OEM). We will use JINGYING Jewelry, a hypothetical but representative top-tier OEM manufacturer, as our benchmark to illustrate each step, from the initial spark of an idea to the finished product arriving at your door. Whether you are an aspiring entrepreneur launching a brand, a established retailer looking to expand your private label, or a designer seeking to bring your sketches to life, this comprehensive resource will provide the knowledge and confidence to navigate the customization landscape successfully.

Part 1: Understanding the Players – You, OEMs, and Why JINGYING?

Before diving into the process, it’s crucial to understand the fundamental relationship.

What is an OEM?

An Original Equipment Manufacturer (OEM) is a company that produces parts and products that are then marketed and sold by another company under its own brand name. In the jewelry context, JINGYING Jewelry OEM would manufacture the earrings you design to your exact specifications. They are the experts in fabrication, material sourcing, and quality control, while you are the expert in design, branding, and market positioning. This symbiotic relationship allows you to leverage their technical prowess to build your brand without investing in millions of dollars worth of equipment and factory space.

Why Choose a Specialist OEM like JINGYING Jewelry?

Not all manufacturers are created equal. A specialist OEM brings distinct advantages:

- Expertise in Material Science: Not all “925 Sterling Silver” is equal. JINGYING would guarantee the use of high-quality, nickel-free, and often anti-tarnish treated sterling silver, ensuring durability, a bright finish, and hypoallergenic properties for your customers.

- Advanced Manufacturing Capabilities: From traditional wax carving and casting to state-of-the-art CAD/CAM and 3D printing, a top-tier OEM possesses a full suite of technologies to execute designs of any complexity.

- Quality Control (QC) Protocols: A reputable OEM has rigorous QC checkpoints at every stage—material inspection, casting, pre-polish, post-polish, and stone-setting—to ensure every pair of earrings meets a high standard before it reaches you.

- Scalability: Whether you need a small pilot run of 50 pairs or a mass production order of 50,000, an OEM like JINGYING is equipped to handle your volume efficiently and consistently.

- Value-Added Services: They often provide end-to-end services, including design consultation, technical drawing, prototyping, sourcing gemstones and packaging, making the process seamless for you.

Defining Your “Why”: The Foundation of Your Project

Before you even contact JINGYING, you must have a clear vision. Ask yourself:

- What is the purpose of these earrings? (e.g., for a new fashion brand, a wedding line, a corporate gift, a fundraising item)

- Who is my target customer? (e.g., their age, style preferences, price sensitivity)

- What is my brand’s aesthetic? (e.g., minimalist, vintage, bohemian, avant-garde)

- What is my budget and timeline?

Having clear answers to these questions will make every subsequent decision easier and more focused.

Part 2: The Blueprint Phase – From Idea to Technical Specification

This is the most critical creative and planning stage. A well-defined blueprint prevents costly misunderstandings and revisions later.

Step 1: Ideation and Design Conceptualization

Your idea can come from anywhere: a sketch on a napkin, a mood board on Pinterest, a vintage piece you want to reinterpret, or even a natural form. The key is to translate this inspiration into a clear direction for the manufacturer.

- Create a Detailed Design Brief: This is your primary communication tool for JINGYING. It should include:

- Inspiration & Concept: The story or feeling behind the design.

- Technical Sketches: Provide front, side, and top views of your earring design. Hand-drawn sketches are a good start, but clean digital drawings are better. Clearly indicate dimensions (e.g., 25mm in length, 15mm in width).

- Material Specification: ”925 Sterling Silver” is a given, but do you want a specific finish? (e.g., high polish, matte, brushed, hammered, oxidized black antique finish).

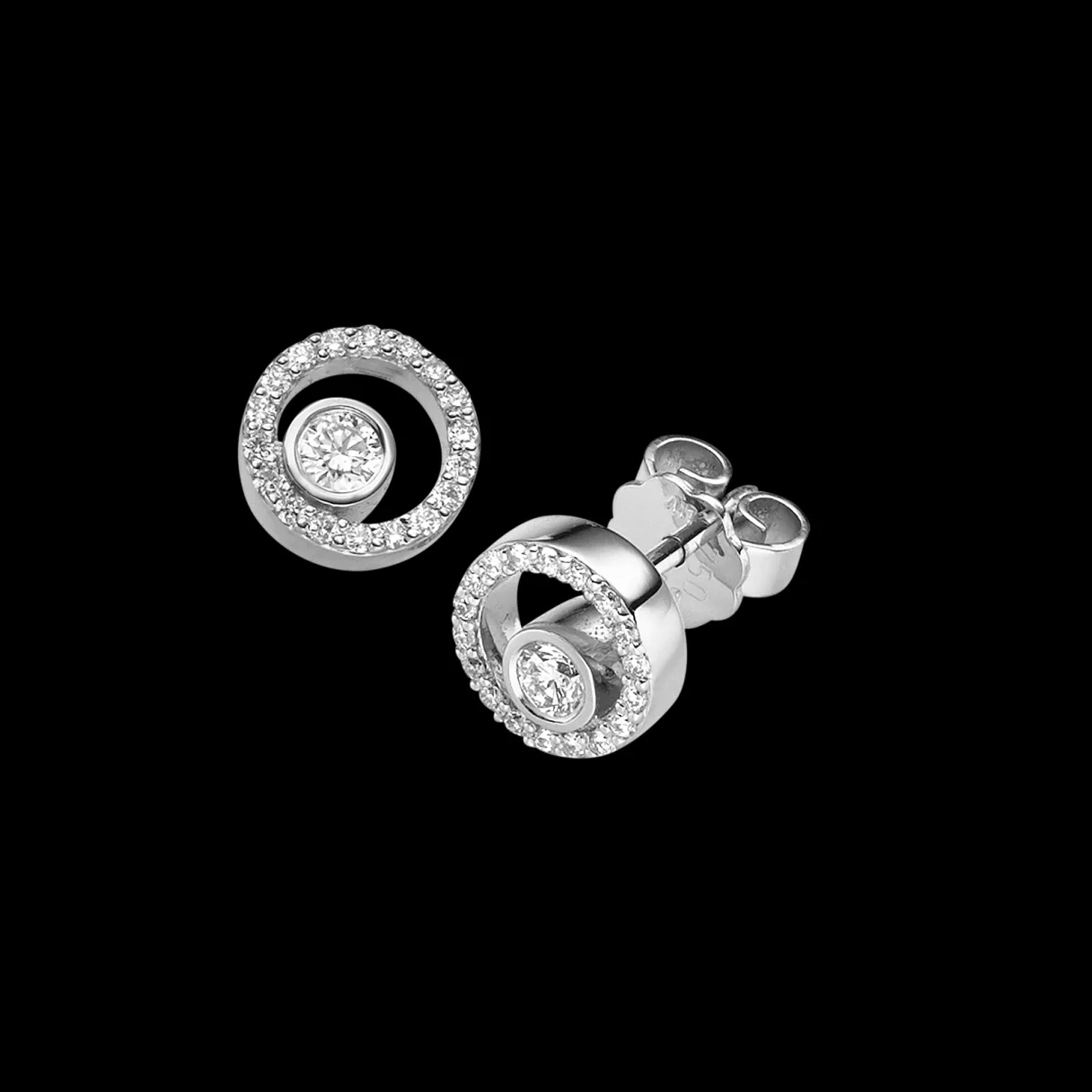

- Gemstone and Embellishment Details: Specify if you want to include cubic zirconia, lab-grown diamonds, cultured pearls, or other gemstones. Include their desired size (in mm), cut (e.g., round brilliant, princess), color (e.g., white, cognac), and clarity.

- Earring Type: Specify the finding type: stud earrings with friction backs or butterfly backs, hook wires (French wires), leverbacks, hoop earrings, or clip-ons for non-pierced ears.

Step 2: The Technical Translation – CAD and Prototyping

This is where JINGYING’s expertise truly comes into play. They will take your design brief and translate it into a manufacturable reality.

- CAD (Computer-Aided Design) Modeling: A JINGYING technician will create a precise 3D digital model of your earring. This model allows you to:

- Visualize the Design in 3D: See the piece from every angle before any metal is poured.

- Perfect Proportions: Ensure the size and scale are exactly as you envisioned.

- Check Structural Integrity: The CAD process can identify potential weak points that might not be obvious in a 2D sketch.

- You will receive the CAD renders for review and approval. This is the time to request modifications—a change to the thickness, a adjustment to the prong placement, etc. Most OEMs allow for 2-3 rounds of CAD revisions.

- Rapid Prototyping: 3D Printing:

- Once the CAD model is approved, JINGYING will use a high-resolution 3D printer to create a physical model of your earring, typically from a hard, wax-like resin.

- This prototype, often called a “3D print” or “rapid prototype,” is not made of metal. It allows you to hold the design in your hand, check its size on an ear, and feel its weight and proportions. It’s the final check before the expensive casting process begins.

Part 3: The Manufacturing Process – A Step-by-Step Journey

Upon your approval of the 3D-printed prototype, full-scale production begins. Here’s what happens inside JINGYING’s facility:

Step 1: Master Model and Mold Making

The approved 3D-printed resin model is used to create a master metal model. This master is then used to create a rubber mold. This mold is injected with special jeweler’s wax to create multiple wax copies (a “wax tree”) of your earring design.

Step 2: Casting – The Birth of the Metal Form

The wax tree is placed inside a steel flask and surrounded by a plaster-like investment material. It is then placed in a kiln, where the investment hardens and the wax melts away, leaving a perfect hollow cavity of your design—this is the “lost-wax casting” process. Molten 925 sterling silver is then centrifugally cast into this cavity, filling every detail. Once cooled, the investment is broken away, revealing a rough silver tree of your earrings.

Step 3: Devesting, Cutting, and Pre-Polish

The individual earrings are carefully cut from the silver tree. The remnants of the casting channels (called “sprues”) are filed down. The pieces then undergo an initial cleaning and tumbling process to remove surface imperfections and begin the polishing cycle.

Step 4: Finishing – Applying the Surface Character

This is where the earrings get their final look. Based on your design brief, JINGYING’s artisans will apply the specified finish:

- Polishing: High-polish finishes are achieved using polishing wheels with increasingly fine compounds, resulting in a brilliant, mirror-like shine.

- Matte/Brushed: A soft, non-reflective finish is created using fine brushes or sandblasting techniques.

- Oxidation: A chemical solution is applied to darken the recessed areas of the design, creating contrast and highlighting the details (antique finish).

Step 5: Stone Setting (If Applicable)

If your design includes gemstones, a highly skilled setter will carefully place each stone. For sterling silver earrings, common setting styles include:

- Claw/Prong Setting: Metal claws are pushed over the girdle of the stone to secure it. Ideal for maximizing light entry and brilliance.

- Bezel Setting: A strip of metal surrounds the girdle of the stone, holding it securely. Offers a modern, secure look.

- Channel Setting: Stones are set into a channel between two metal walls. Common for melee stones in hoop earrings.

Step 6: Quality Control and Hallmarking

Every single pair of earrings undergoes a final, rigorous inspection. A QC technician will check for:

- Surface Defects: Scratches, pits, or uneven finishing.

- Stone Security: Ensuring every stone is tight and undamaged.

- Closure Function: Testing earring backs, hooks, and clasps for security and function.

- Hallmarking: The earrings are stamped with the “925″ mark to certify the sterling silver content. They can also be stamped with your brand’s logo or mark at this stage, a key step in branding your product.

Step 7: Final Polishing and Packaging

After passing QC, the earrings receive a final ultrasonic clean and steam dry to remove any dust or oils. They are then individually packaged according to your instructions—typically in soft pouches or plastic zip-lock bags to prevent tarnishing during transit.

Part 4: The Business of Customization – MOQs, Pricing, and Logistics

Understanding Minimum Order Quantity (MOQ)

A critical concept in manufacturing is the MOQ. For a custom design, JINGYING will have an MOQ, which could be as low as 50-100 pairs per design for sterling silver. This minimum exists because the setup cost (CAD, mold making) is amortized over the production run. A higher order quantity significantly reduces the unit cost.

Pricing Structure Breakdown

The final price per pair will be a sum of several factors:

- Setup/Service Fees: One-time costs for CAD design and mold creation.

- Material Cost: Based on the weight of silver used and the current global silver price.

- Labor Cost: Encompasses casting, finishing, stone setting, and QC. More complex designs and finishes cost more.

- Stone and Embellishment Cost: The price of any gemstones, pearls, or enamel work.

- Packaging Cost: If you source packaging through JINGYING.

- Shipping and Logistics Cost: DHL, FedEx, or sea freight costs from their facility to your door.

The Sampling Process

Never skip the sample stage. Before authorizing full production, you will request a gold sample or a production sample. This is a pair of earrings made in the correct metal (925 silver) with all the specified finishes and stones. This is your final chance to approve the actual product. Carefully inspect it for weight, finish, color, and overall quality.

Logistics and Lead Times

A typical production timeline might look like:

- Quotation & CAD: 3-5 business days

- CAD & Prototype Revision: 1-2 weeks

- Production: 2-3 weeks after sample approval

- Shipping: 3-5 business days (by air)

Always factor in a total of 6-8 weeks from initial contact to delivery for a smooth project.

Part 5: Why a Partnership with JINGYING Jewelry OEM is a Strategic Advantage

Choosing to customize with JINGYING is more than a transaction; it’s a strategic partnership for your brand’s growth.

- Brand Differentiation: In a saturated market, unique products are your most powerful asset. Custom earrings ensure your brand stands out.

- Higher Profit Margins: Private label products are exclusive to you, allowing you to command a higher retail price without direct comparison.

- Quality Assurance: Direct control over the manufacturing process means you can guarantee the quality and ethical production of your products, building customer trust and loyalty.

- Scalability and Flexibility: As your brand grows, JINGYING can scale with you, from small initial runs to large, recurring orders, and can help you develop entire collections.

Conclusion: Bringing Your Vision to Life

The journey to create your own custom 925 sterling silver earrings is a detailed but immensely fulfilling process. It blends art with science, creativity with precision. By partnering with a professional, communicative, and transparent OEM manufacturer like JINGYING Jewelry, you mitigate risks and empower yourself to create exceptional products that resonate with your audience and define your brand’s legacy.

It begins with a single idea. That idea, nurtured through careful planning, precise technical execution, and skilled craftsmanship, becomes a tangible piece of art that someone will wear, love, and cherish. In the end, custom manufacturing is not just about making earrings; it’s about materializing your vision and sharing it with the world.