Custom Cubic Zirconia pendant necklace OEM/ODM Service

Makes custom jewelry supplier

LET’S GET STARTED : mo@kingjy.com

Custom Cubic Zirconia Pendant Necklace OEM/ODM Services: A Comprehensive Guide

Table of Contents

- Introduction

- The Growing Popularity of Cubic Zirconia Jewelry

- Understanding OEM vs. ODM Jewelry Manufacturing

- Why Choose Custom Cubic Zirconia Pendant Necklaces?

- Design Options for Cubic Zirconia Pendants

- Materials Used in CZ Pendant Necklaces

- The Manufacturing Process: From Concept to Finished Product

- Quality Control and Certification Standards

- Packaging and Branding for Private Label Jewelry

- Minimum Order Quantity (MOQ) and Pricing Considerations

- Sustainable and Ethical Manufacturing Practices

- Case Study: Successful OEM/ODM CZ Pendant Necklace Production

- How to Choose the Right OEM/ODM Manufacturer

- Marketing and Selling Custom CZ Jewelry

- Future Trends in Cubic Zirconia Jewelry

- Conclusion

1. Introduction

The jewelry industry is evolving rapidly, with consumers increasingly seeking affordable yet luxurious alternatives to diamonds. Cubic Zirconia (CZ) has emerged as a top choice due to its brilliance, durability, and cost-effectiveness. For jewelry brands and retailers, OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services provide the perfect solution for creating custom CZ pendant necklaces that align with market trends and brand identity.

This guide explores:

- The benefits of cubic zirconia jewelry

- The OEM/ODM manufacturing process

- How to select the right manufacturer for custom CZ pendant necklaces

2. The Growing Popularity of Cubic Zirconia Jewelry

Cubic Zirconia has gained immense popularity due to:

✔ Diamond-like brilliance – CZ stones mimic the sparkle of diamonds at a fraction of the cost.

✔ Affordability – Ideal for fashion jewelry and luxury-inspired collections.

✔ Durability – Rated 8.5 on the Mohs scale, making it resistant to scratches.

✔ Versatility – Available in various cuts (round, princess, emerald, etc.) and colors.

With rising demand for ethical and budget-friendly jewelry, CZ is a preferred choice for brands and consumers alike.

3. Understanding OEM vs. ODM Jewelry Manufacturing

OEM (Original Equipment Manufacturing)

- Custom designs based on your specifications

- Full control over materials, stone shapes, and metal types (sterling silver, gold-plated, etc.)

- Ideal for brands with unique design concepts

ODM (Original Design Manufacturing)

- Pre-designed models that can be customized (e.g., adjusting stone size or metal finish)

- Faster production turnaround

- Best for brands looking for ready-made solutions

4. Why Choose Custom Cubic Zirconia Pendant Necklaces?

Benefits for Jewelry Brands:

- Brand Differentiation – Unique designs set your products apart.

- Cost-Effective Production – Lower material costs than diamonds.

- Wide Appeal – Suitable for everyday wear, bridal jewelry, and fashion statements.

Popular CZ Pendant Styles:

- Solitaire CZ Pendants – Classic and elegant

- Halo Designs – Enhances brilliance with surrounding stones

- Custom Shapes (Hearts, Crosses, Geometric Patterns)

5. Design Options for Cubic Zirconia Pendants

When ordering OEM/ODM CZ pendant necklaces, consider:

✔ Stone Size & Cut – Round, oval, pear, or custom shapes

✔ Metal Choices – 925 Sterling Silver, 14K/18K Gold Plated, Rose Gold

✔ Setting Styles – Prong, bezel, or tension setting

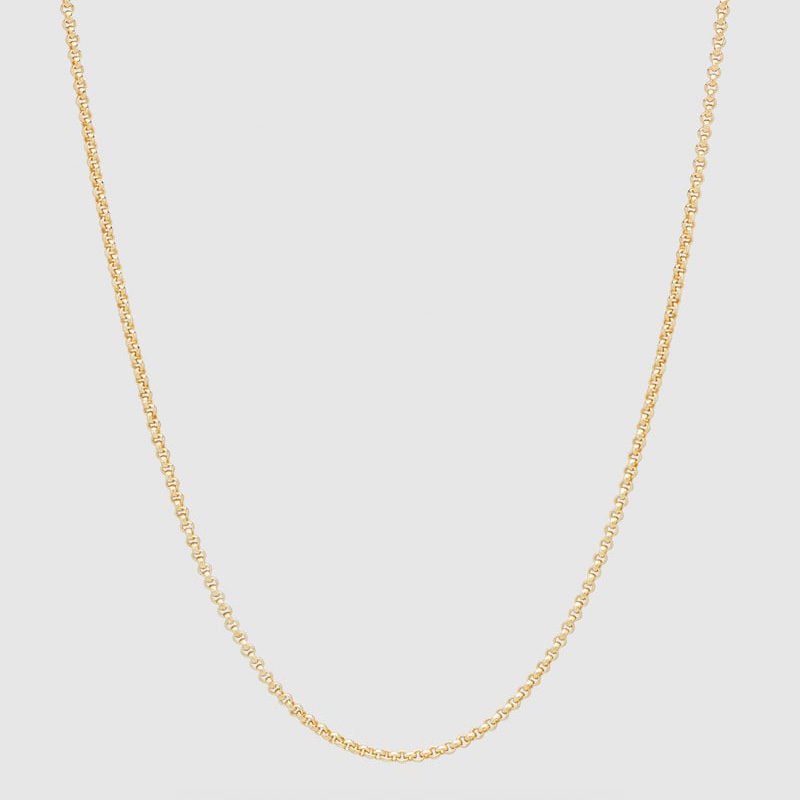

✔ Chain Options – Cable, Figaro, Box, or Rope chains

6. Materials Used in CZ Pendant Necklaces

- Cubic Zirconia (CZ) – High-quality lab-created stones with excellent clarity.

- Sterling Silver (925 Silver) – Durable and hypoallergenic.

- Gold-Plated & Rose Gold-Plated – Adds a luxury touch.

- Rhodium Plating – Enhances shine and prevents tarnishing.

7. The Manufacturing Process: From Concept to Finished Product

- Design & 3D Modeling – CAD designs for precision.

- Prototyping – Wax or 3D-printed samples for approval.

- Stone Setting & Casting – Expert craftsmanship.

- Polishing & Plating – Ensures a flawless finish.

- Quality Inspection – Checks for defects before shipment.

8. Quality Control and Certification Standards

Reputable manufacturers follow strict QC measures:

- Gemstone Inspection – No visible flaws in CZ stones.

- Metal Purity Testing – Ensures 925 silver or proper gold plating.

- International Certifications – SGS, ISO, and RoHS compliance.

9. Packaging and Branding for Private Label Jewelry

- Custom Jewelry Boxes – Luxury packaging options.

- Branded Tags & Inserts – Enhances brand identity.

- Eco-Friendly Packaging – Sustainable alternatives.

10. Minimum Order Quantity (MOQ) and Pricing Considerations

- Low MOQ Options – Some suppliers accept 50-100 pieces.

- Bulk Discounts – Lower per-unit cost for larger orders.

- Factors Affecting Pricing – Metal type, stone size, and labor costs.

11. Sustainable and Ethical Manufacturing Practices

- Conflict-Free CZ Stones – Ethically sourced materials.

- Recycled Metals – Eco-friendly production.

- Fair Labor Practices – Safe working conditions.

12. Case Study: Successful OEM/ODM CZ Pendant Necklace Production

Example: A fashion brand collaborated with an OEM manufacturer to create a custom heart-shaped CZ pendant necklace in rose gold.

- Process: Design consultation → 3D prototyping → Mass production.

- Result: A best-selling product with high customer satisfaction.

13. How to Choose the Right OEM/ODM Manufacturer

- Experience & Portfolio – Check past CZ jewelry projects.

- Customization Flexibility – Can they meet unique design requests?

- Communication & Lead Time – Responsive and transparent.

14. Marketing and Selling Custom CZ Jewelry

- E-Commerce & Social Media – Instagram, TikTok, and Pinterest.

- Influencer Collaborations – Boosts brand visibility.

- Retail & Wholesale Distribution – Expand market reach.

15. Future Trends in Cubic Zirconia Jewelry

- Lab-Grown Colored CZ – Unique hues for statement pieces.

- Minimalist & Stackable Designs – Catering to Gen Z trends.

- Smart Jewelry Integration – CZ pendants with tech features.

16. Conclusion

Custom cubic zirconia pendant necklaces offer endless possibilities for jewelry brands through OEM/ODM manufacturing. By partnering with the right manufacturer, businesses can create high-quality, affordable, and stylish jewelry that meets consumer demand.