Crafting 20,000 Custom 925 Sterling Silver Necklaces with Rose Gold-Plated Pendants for a Portuguese Client

OEM/ODM jewelry manufacturer design custom your own jewelry

LET’S GET STARTED : mo@kingjy.com

A Sparkling Collaboration: Crafting 20,000 Custom 925 Sterling Silver Necklaces with Rose Gold-Plated Pendants for a Portuguese Client

Introduction

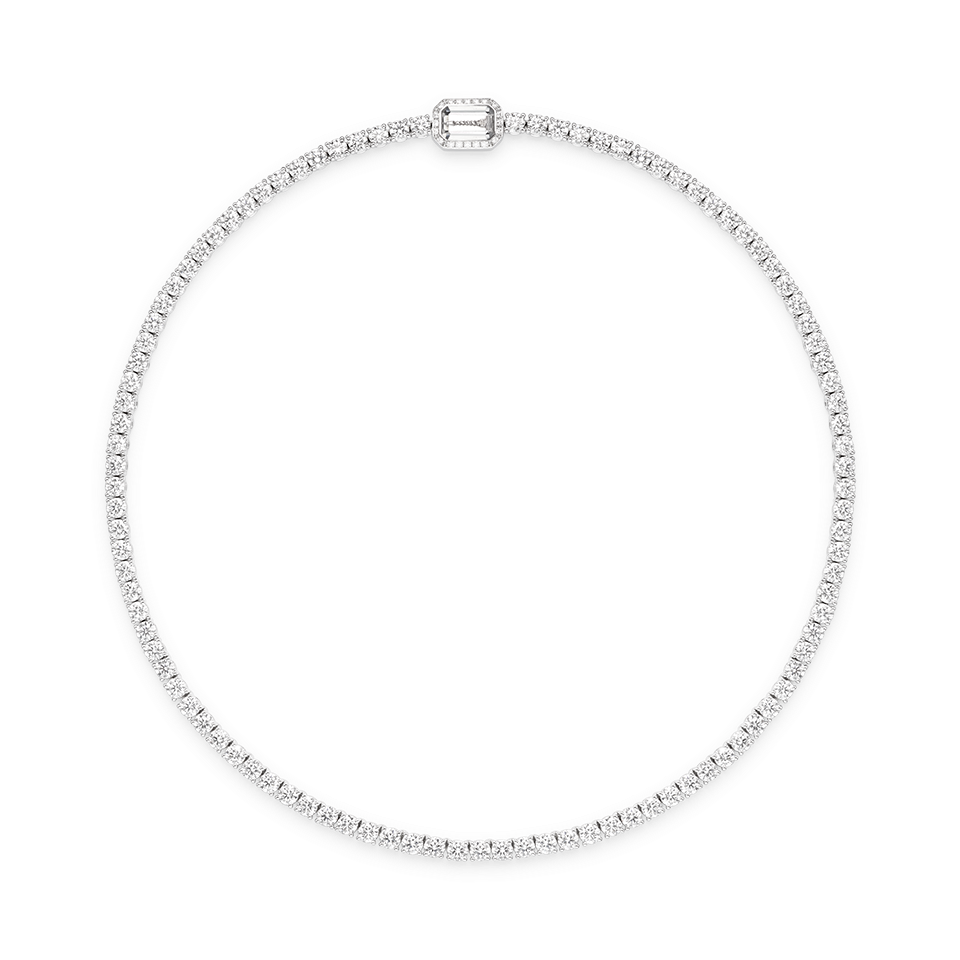

In the world of jewelry manufacturing, custom orders are a testament to a brand’s craftsmanship, attention to detail, and ability to meet unique client specifications. One such noteworthy project was undertaken by JINGYING, a renowned jewelry manufacturer known for its precision and quality. The company received a significant order from a client in Portugal: 20,000 bespoke 925 sterling silver necklaces, each featuring a rose gold-plated pendant. This article delves into the intricacies of this project, highlighting the design process, production challenges, quality assurance measures, and the successful delivery that strengthened the business relationship between JINGYING and its Portuguese client.

Chapter 1: Understanding the Client’s Vision

The journey began with a comprehensive consultation between JINGYING’s design team and the Portuguese client. The client envisioned a necklace that embodied elegance and sophistication, suitable for both everyday wear and special occasions. The choice of 925 sterling silver as the base material was deliberate, known for its durability and lustrous finish. The addition of rose gold plating was intended to provide a modern twist, appealing to contemporary fashion trends.

The design process involved multiple iterations to ensure that the pendant’s shape, size, and finish aligned with the client’s expectations. The client provided sketches and mood boards, which JINGYING’s team used as a foundation to create digital prototypes. These prototypes were shared with the client for feedback, ensuring that every detail met their approval before moving forward.

Chapter 2: Material Selection and Sourcing

Selecting the right materials was crucial for the success of this project. JINGYING sourced high-quality 925 sterling silver from reputable suppliers, ensuring that the metal met international standards for purity and strength. The rose gold plating was applied using advanced electroplating techniques to achieve a consistent and durable finish.

To maintain the integrity of the design, the team also considered the type of chain that would complement the pendant. After evaluating various options, a delicate yet sturdy chain was chosen to enhance the overall aesthetic without overshadowing the pendant.

Chapter 3: Prototyping and Client Approval

Before commencing mass production, JINGYING produced a limited number of prototypes to present to the client. These prototypes allowed the client to assess the design in real-world conditions, providing valuable insights into aspects such as weight, comfort, and overall appearance.

The client provided feedback on the prototypes, requesting minor adjustments to the clasp mechanism for improved ease of use. JINGYING promptly implemented these changes and resubmitted the revised prototypes for final approval. This collaborative approach ensured that the final product would meet the client’s high standards.

Chapter 4: Mass Production and Quality Control

With the design finalized and approved, JINGYING initiated mass production. The process was meticulously planned to ensure efficiency and consistency across all 20,000 units. Skilled artisans handcrafted each pendant, paying close attention to detail to maintain uniformity in size, shape, and finish.

Quality control was a top priority throughout the production process. Each piece underwent rigorous inspections at various stages, including pre-plating, post-plating, and final assembly. The quality control team checked for defects such as scratches, uneven plating, and structural integrity issues. Only pieces that met the stringent quality standards were approved for packaging.

Chapter 5: Packaging and Logistics

Once the necklaces passed quality control, they were carefully packaged to prevent damage during transit. JINGYING collaborated with logistics partners to ensure timely and secure delivery to Portugal. The packaging was designed not only to protect the jewelry but also to reflect the brand’s commitment to quality and attention to detail.

The logistics team coordinated the shipment, ensuring that all necessary documentation was in order for customs clearance. The necklaces were shipped via air freight to expedite delivery, with tracking systems in place to monitor the shipment’s progress.

Chapter 6: Delivery and Client Satisfaction

Upon arrival in Portugal, the necklaces underwent a final inspection by the client. They were pleased to find that the products matched the approved prototypes in every aspect. The client expressed their satisfaction with the craftsmanship and quality of the necklaces, noting that they had already received positive feedback from their customers.

The successful completion of this project not only fulfilled the client’s order but also strengthened the business relationship between JINGYING and the Portuguese client. The collaboration demonstrated JINGYING’s ability to handle large-scale custom orders while maintaining high standards of quality and customer service.

Chapter 7: Lessons Learned and Future Collaborations

The project provided valuable lessons for both JINGYING and the client. Effective communication and collaboration were key to overcoming challenges and ensuring that the final product met expectations. The experience also highlighted the importance of thorough quality control and logistical planning in delivering large orders on time.

Looking ahead, both parties expressed interest in future collaborations. The success of this project has paved the way for potential new designs and product lines, further solidifying the partnership between JINGYING and its Portuguese client.

Conclusion

The completion of the 20,000 custom 925 sterling silver necklaces with rose gold-plated pendants for the Portuguese client stands as a testament to JINGYING’s dedication to quality, craftsmanship, and customer satisfaction. Through meticulous planning, design, and execution, the company was able to deliver a product that not only met but exceeded the client’s expectations. This project exemplifies the potential of international collaborations in the jewelry industry, where shared vision and expertise can lead to the creation of exceptional products.